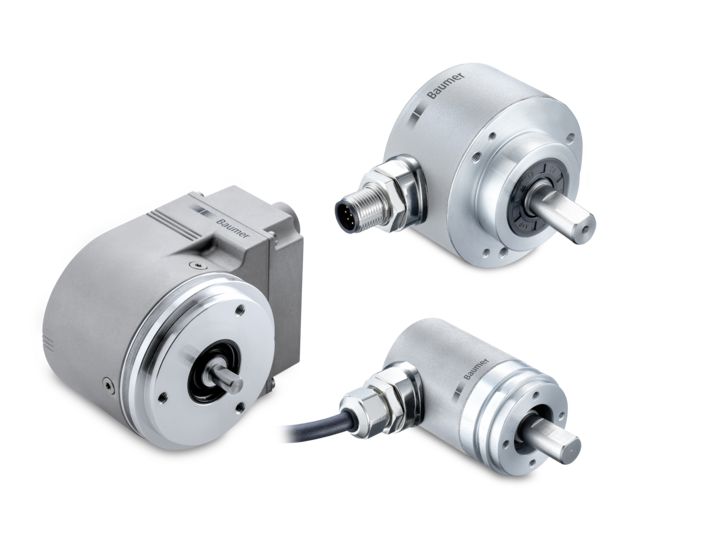

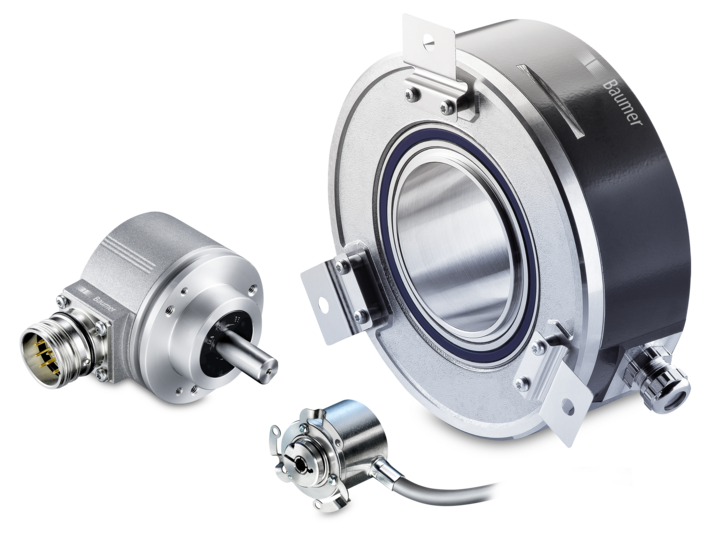

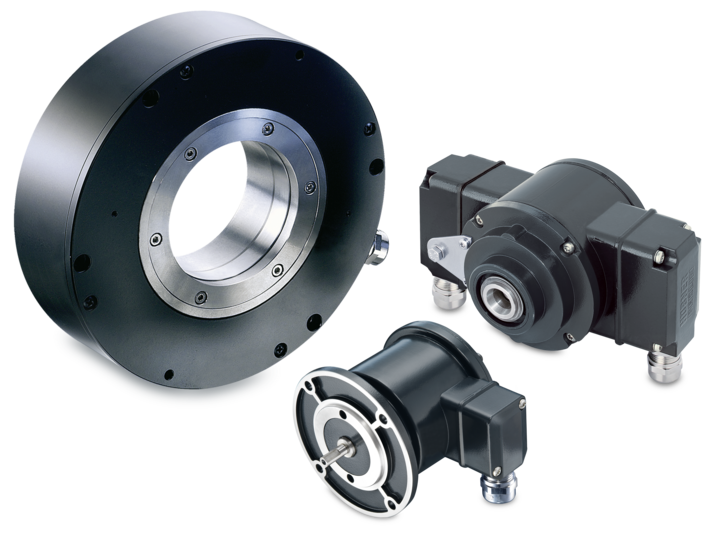

제품 포트폴리오

Applications

Bearingless encoders have proven themselves in numerous industries. For designers of machining centers, wind turbines, mobile vehicles, elevators or textile machines, the non-contact sensing principle opens up new flexibility: they are more compact, easy to integrate, independent of the shaft diameter and yet robust against harsh ambient impacts. They integrate in former inaccessible places and leave room for further design improvements. Overall costs from design-in to maintenance are significantly reduced.

Your benefits

- Low development and manufacturing costs

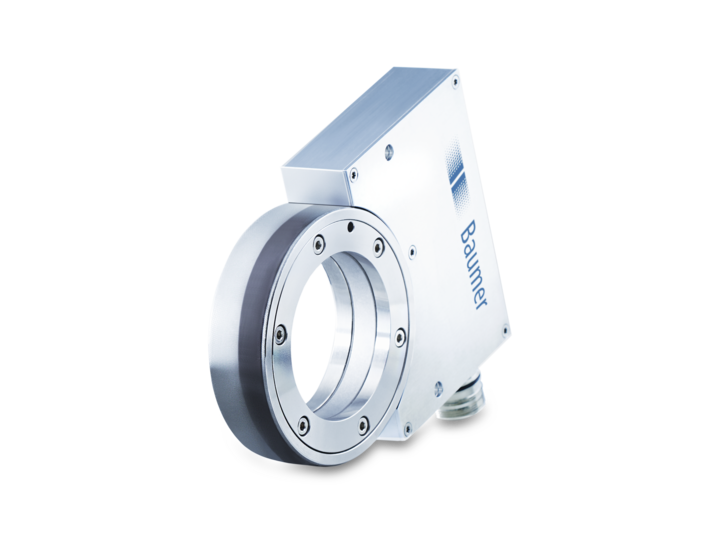

- Due to flexibility in shaft diameters from 6 mm on to more than 3 m, the encoder will adapt to your design and not vice versa

- Compact machine design

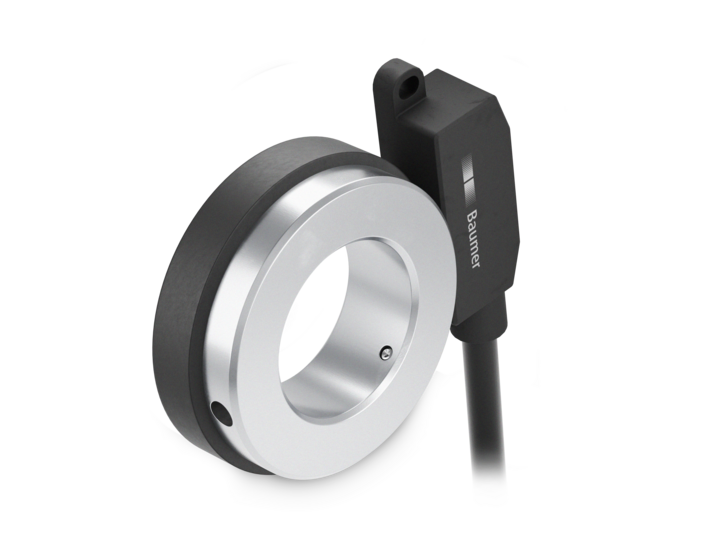

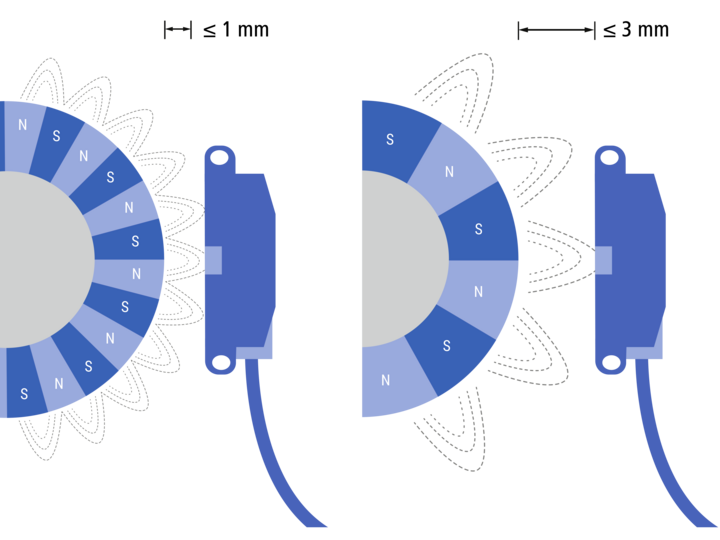

- Shallow installation depth thanks to radial sensing

- Solutions with installation depths of less than 12mm

- Integration flexibility through A- or B-side mount

- Reliable long-term operation even under extreme conditions

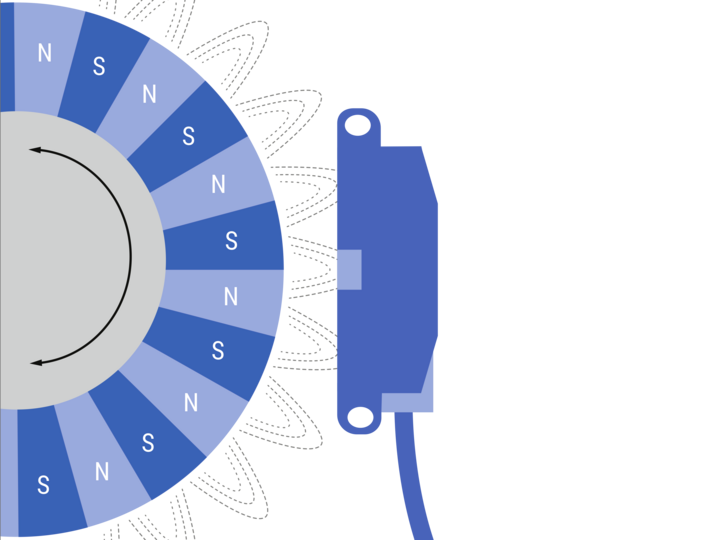

- Wear-free non-contact magnetic sensing

- Resistant to dirt

- Resistant to shocks and vibration

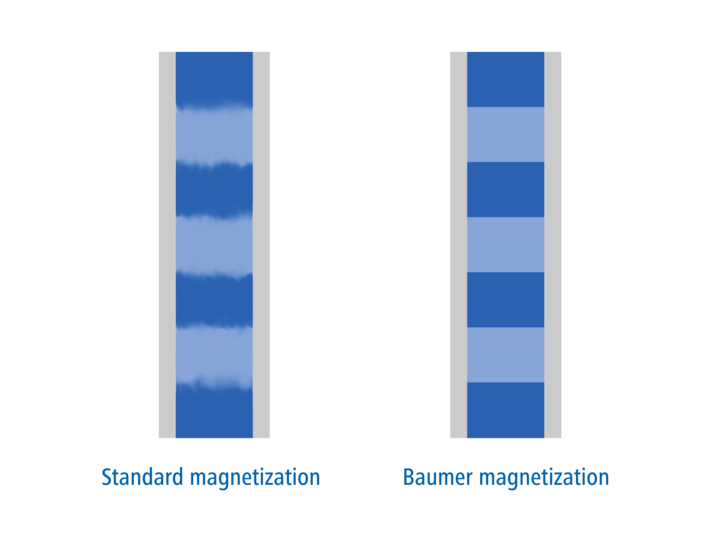

- Excellent speed quality thanks to precise magnetization

- High-precision magnetic wheels thanks to long-year magnetization expertise

- Long-term high IP protection

- The bearingless design and fully encapsulated electronics allows for cost-efficient but yet high IP protection

- Even at high speeds, the encoder remains protected from water and dust ingress

- Improved robustness by electronics being decoupled from moving parts

- Immune to shaft currents

- Particularly the ball bearings in rotary encoders installed at powerful electric drives may be exposed to current overshoots

- The sensor head being decoupled from shaft will solve the problem

- Easy-to-implement redundancy

- Two sensor heads on a single magnetic wheel is redundant sensing made easy

Applications

Angle and position measurements and speed feedback

- Motor feedback

- Textile machinery

- Printing machinery

- Elevator construction

- Wind power plants

- Hydro power stations

- Large drives (rolling mills, steel mills)

- Generators

- Azimuth drives (POD)

- Crane systems

- Paper machines

Technological highlights

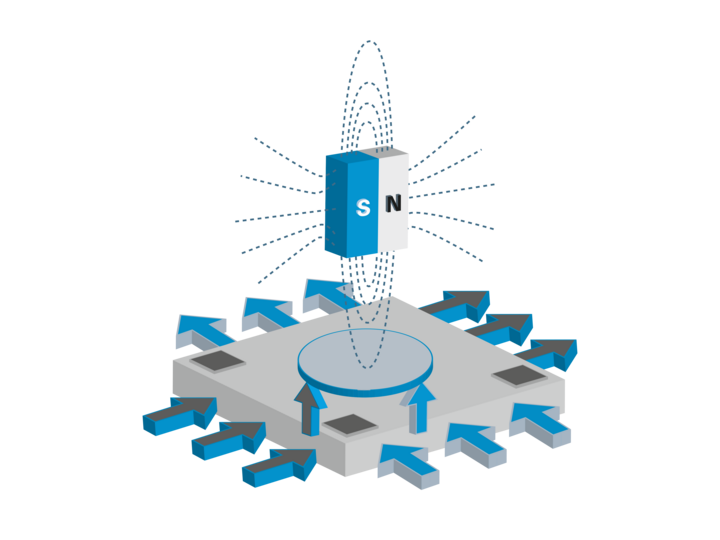

Magnetic sensing allows for a large gap between sensor and material measure (usually a magnetic wheel or center magnet). Therefore they can be positioned separately from each other and it eliminates the need for precision ball bearings usually used in rotary encoders. And, this provides quite high installation tolerances. This provides more flexibility in design and installation. As there is no need for bearings, there is no conventional wear and tear either.

This way the encoders withstand dust, dirt or textile fibers. They are immune to shaft currents or bearing loads and robust against vibration and shock.