Switzerland

ch

English

High quality products also with maximum food safety in different packaging – these consumer requirements greatly influence the production processes and quality control. These factors in turn are used as the requirement profiles for our sensors. With our corresponding technologies we support the required flexibility in the most diverse machine applications.

Level monitoring in packaging

Ultrasonic distance sensor with extremely narrow sound beam

High quality assurance

- Linearized measuring range with 0.5 mm repeat accuracy

- Reliable ultrasonic retroreflective barrier principle

Reduced decision-making costs

- Up to 150 mm detection range for a diverse range of media

- Response times of less than 7 ms (measuring)

- Response times of 1.3 ms (switching)

Trigger sensor for smart camera

Diffuse sensors with background suppression

Reduced production costs and times

- Visible light spot for easy sensor alignment

- No reflector necessary

High operational reliability

- High machine flexibility as different colors and shapes are reliably detected

- Immunity to background reflections and extraneous light ensures a stable detection process

Speed-independent triggering

Direct connection of incremental rotary encoder to the smart camera for speed-independent quality control

High quality control reliability

- Virtually jitter-free rotary encoder signals allow precision camera triggering over the entire speed range

- Monolithic opto-ASIC with high integration density facilitates stable signals even under shock and vibration conditions in continuous operation

- Robust sealing concept for guaranteed high protection class IP 67

High degree of flexibility

- Flexible parameterization from 1 ... 65536 pluses/ revolution

- Selectable TTL or HTL output signal level

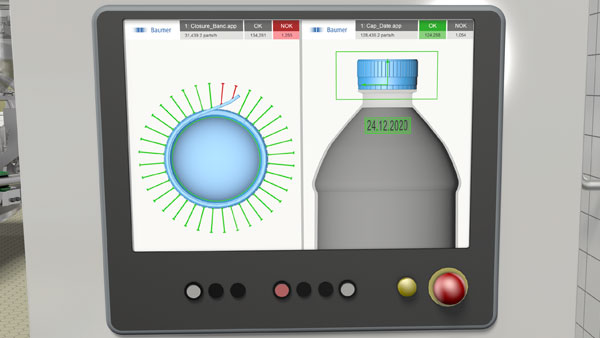

Quality control of filled containers

Image processing and identification with vision sensor

High operational reliability

- Contour-based evaluation by FEX® image processor for stable quality control also with fluctuating surface properties

- Easy and reliable setup of color checks with ColorFEX® 3D color assistant

- Robust thanks to industrial design in rugged metal enclosure of protection class IP 67

High degree of flexibility

- No mechanical object alignment necessary thanks to automatic FEXLoc® 360 ° position tracking

- 22 different check tools are able to check up to 32 features per job

- Up to 255 jobs can be stored in the sensor with backup option via FTP server

- High-speed mode with up to 100 checks/minute

- XC series with interchangeable lenses, including patented modular IP 67 lens protection

Live image quality assurance

Web interface with MultiViewer to display up to 16 VeriSens® on one screen

Reduced implementation time and costs

- Configurable web interface for application-specific operation and monitoring in only a few minutes

- No additional software costs

- Integrated VeriFlash flash controller for reduced programming and integration expenditure

- Error image memory in sensor

- Integrated FTP client allows error images to be stored on a FTP server