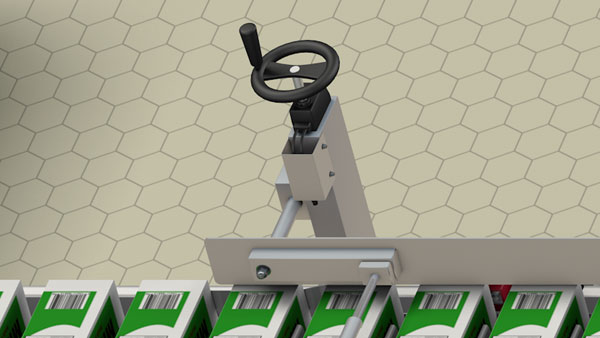

Efficient spindle positioning on packaging machines...

...becomes necessary as soon as the products to be packaged also change in their dimensions. Packaging machines must be fast and flexible to efficiently package the high product variety and small batch sizes on the same machine. At the same time, process reliability is required in all industries, which is also supported by the spindle position display.

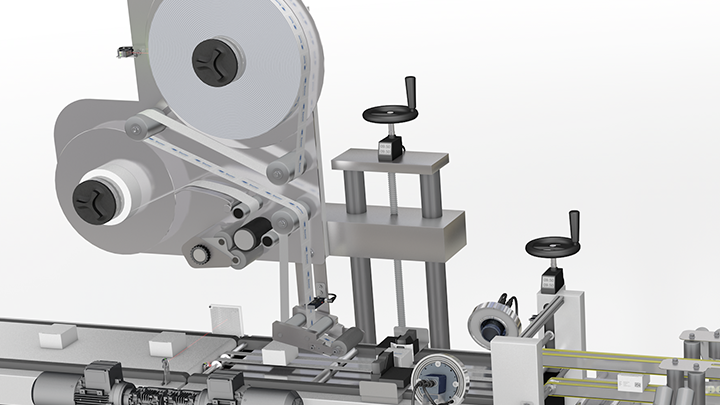

Baumer offers spindle position displays for packaging and labeling machinery in:

- Primary packaging

- Secondary packaging

- End of Line Packing

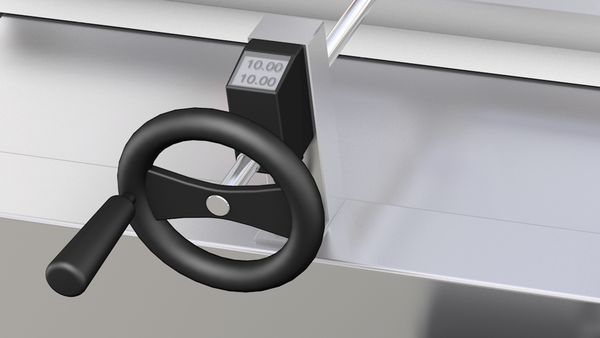

Using a built-in high-resolution optical multiturn absolute encoder, the spindle position indicator achieves the required accuracies of spindle positioning in packaging machines. Even in the absence of power, the spindle position indicator detects an adjustment. This prevents unplanned stops of the machine after restarting.

Packaging machines

Our product

Benefits

The benefits of electronic position displays in multiple manual format adjustment operations per day: