Product portfolio

Highlights

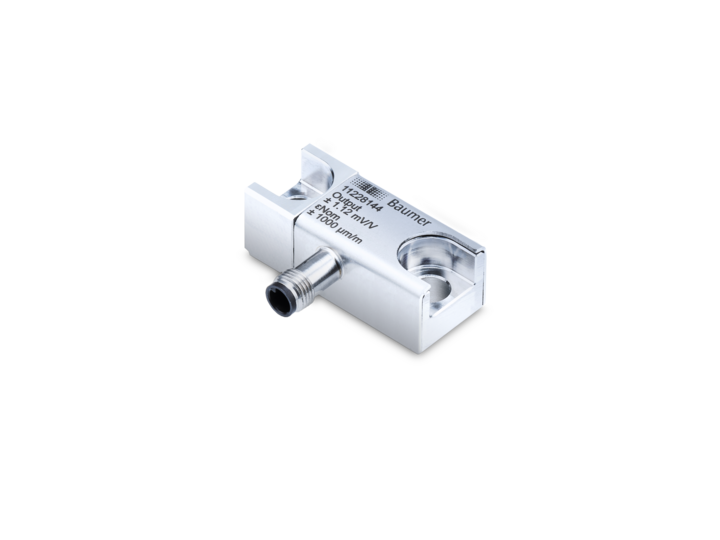

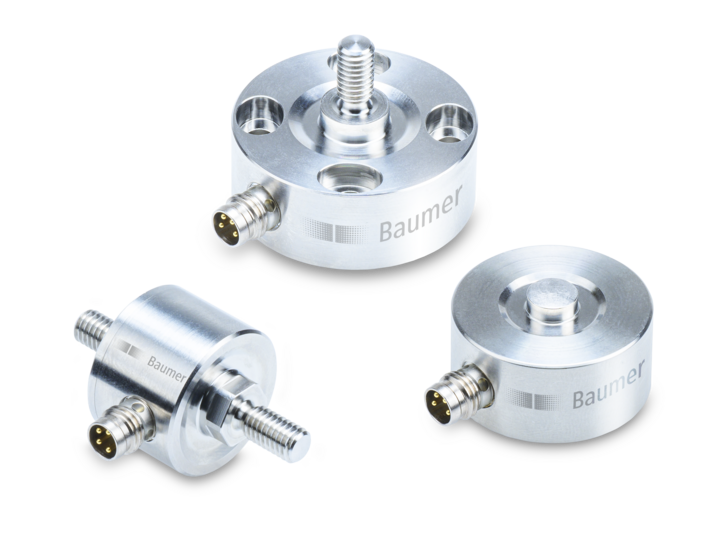

For higher force ranges and large constructions, strain sensors are a suitable alternative to force sensors. Unlike force sensors, strain sensors are not installed directly in the force flow but screwed onto the relevant component surface. The detected surface strain allows for precise force identification without elaborate component modifications.

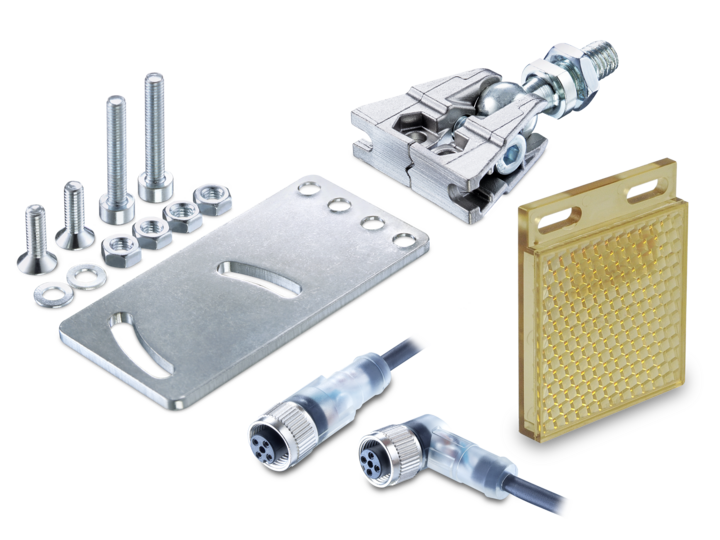

The product portfolio covers the entire sensor range to meet multifacted requirements and specific applications. The portfolio excels in terms of miniaturized and robust products as well as digital connectivity. Consistency that pays off.

Which strain sensor is the right one for your application, how force measurement with strain sensors is implemented and at which position a strain sensor should be mounted, you will find out in our whitepaper.

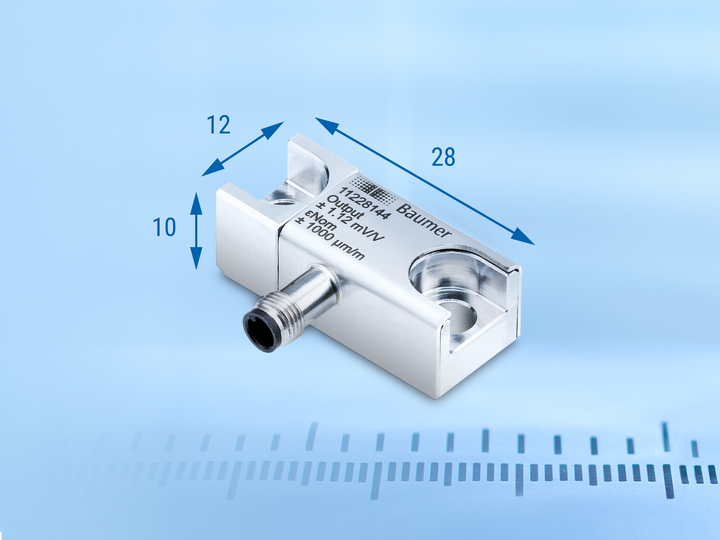

Miniaturization – unparalleled space saving

Robust – Highest operational safety in rough environments

Smart force measurement – simulation, parameterization, intelligent evaluation

Applications

Baumer strain sensors enable cost-effective force measurement for nearly all application areas. Regardless of whether for limited spaces, in robust outdoor applications, or in the industrial sector, we always offer you the right solution for measuring large forces in ongoing processes.

Videos for easy parametrization

Adapt the Baumer force and strain sensors to match your application task of precise force measurements and benefit from smart features for maximum results. Used in combination with the Baumer Sensor Suite, you will fully exploit the capabilities of the force and strain sensors thanks to specific Add-ons and the intuitive user interface. Watch the tutorial and learn more about the Baumer IO-Link portfolio of force and strain sensors.

Your benefits

- The clever alternative to force measurement using force sensors

- Integrates easily into existing machines and facilities

- Minimal engineering effort

- Improved machine capability

- Precise measurement and reliable control of process parameters

- Optimized logistics

- A single sensor will do for different sizes of machines

- Time savings during servicing

- Easy sensor replacement during servicing without the need for time-consuming re-calibration in the machine, thanks to factory-calibrated strain settings

- Quicker and easier sensor installation and exchange

Technology

Standard Baumer strain sensors comprise strain body and strain gauge. The strain sensor is screwed onto a machine structure. The applied force causes deformation at the machine structure which is picked up by the strain body with the help of friction and causing strain on the material surface. The amount of strain is measured by the strain gauge on the strain body surface. The strain gauges convert the mechanical strain into a change in the electrical resistance and act as mechanical-electrical converters. The strain gauges being smartly interconnected to form a Wheatstone bridge allows for measuring even most minor strain. The gauge-measured strain this way generates a change in stress that is proportional to the strain, which can be easily evaluated by the integrated amplifier electronics.

Downloads

Brochures / Catalogs

-

Flyer – Force measurement easily accomplished

Technical and Application Reports / White Paper

-

Technical report – Cost–effective force measurement with DSRT strain sensors

-

Technical Report – Cost-effective clamping force monitoring

-

Technical Report – Innovative vibration damping with strain sensors

-

Technical Report – TipperTie DST55R

-

WP – Force measurement with strain sensors