Germany

de

English

Technical data

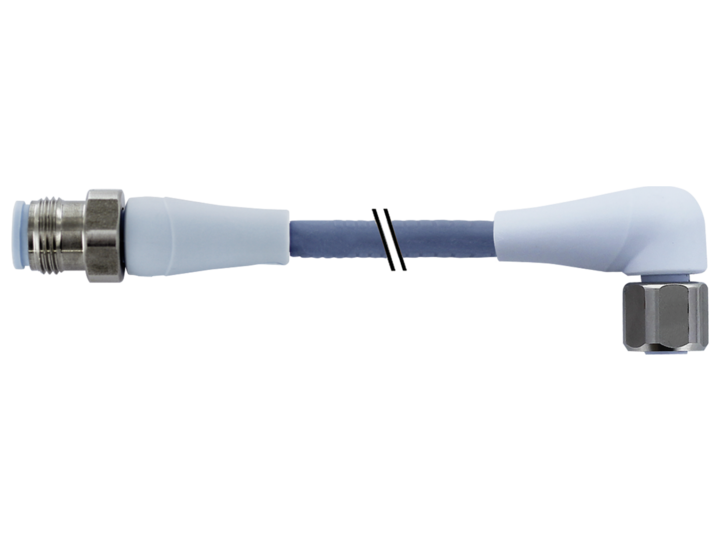

Side A

- Head A: Connection

- M12

- Head A: Angle cable outlet

- 0°

- Head A: Gender

- Male

- Head A: Coding

- A

- Head A: No. of poles

- 5

- Head A: LED

- No

- Head A: Width across flats

- AF14

- Head A: Tightening torque

- 0.6 Nm

- Head A: Knurled nut material

- Stainless steel (V4A)

- Head A: Body color

- Blue

- Labeling sleeve side A

- No

Side B

- Head B: Connection

- M12

- Head B: Angle cable outlet

- 90°

- Head B: Gender

- Female

- Head B: Coding

- A

- Head B: No. of poles

- 5

- Head B: LED

- No

- Head B: Width across flats

- AF14

- Head B: Knurled nut material

- Stainless steel (V4A)

- Head B: Body color

- Blue

- Head B: Gasket material

- EPDM

- Labeling sleeve side B

- No

Cables

- Cable length

- 2500 cm

- Shielded

- No

- AWG

- 22

- External sheath: Material

- TPE-S

- External sheath: Color

- Blue

- Cable diameter

- 4.7 mm ± 5%

- Wire cross section

- 0.34 mm²

Cable

- Operating voltage (only UL listed)

- 30 V AC/DC

- Shielded

- No

- Bending radius (fixed)

- 23.5 mm

- Number of wires

- 5

- Number and diameter of wires

- 5x0.34

- Cable length

- 2500 cm

- AWG

- 22

- Torsion speed

- max. 35 cycles/min

- Wire 1: Color

- BN

- Wire 2: Color

- BK

- Wire 3: Color

- BU

- Wire 4: Color

- WH

- Wire 5: Color

- GY

- Cable diameter

- 4.7 mm ± 5%

- Conductor: Material

- Copper, bare

- External sheath: Material

- TPE-S

- Insulation: Material

- PP

- Paired stranding

- No

- Torsion stress in °

- ± 180 °/m

- Total stranding

- 5 wires strand around core-filler

- Wire cross section

- 0.34 mm²

- Wire processing

- No

- External sheath: Color

- Blue

Electrical data

- Operating voltage (only UL listed)

- 30 V AC/DC

Mechanical data

- Head A: Degree of protection

- IP65, IP68, IP69K

- Head B: Degree of protection

- IP65, IP68, IP69K

- Torsion speed

- max. 35 cycles/min

- Torsion stress in °

- ± 180 °/m

Environmental conditions

- Temperature range (mobile)

- - 25 ...+ 80 °C

- Temperature range (fixed)

- - 25 ...+ 85 °C

- Dragchain capable

- Yes

- Head A: Chemical resistance

- Chemical resistance tested according to ECOLAB. If other media are used, the material resistance must be tested according to the application.

- Head A: Flame resistance

- HB (UL 94)

- Head A: Oil resistance

- Good resistance to ASTM 1 oil and mineral oils. Limited resistance to hydraulic oils. If other oils are used, the resistance must be checked in relation to the application.

- Head A: Acid and alkali resistant

- Chemical resistance tested according to ECOLAB. If other media are used, the material resistance must be tested according to the application.

- Head A: Pollution degree

- 3

- Head B: Chemical resistance

- Chemical resistance tested according to ECOLAB. If other media are used, the material resistance must be tested according to the application.

- Head B: Flame restistance

- HB (UL 94)

- Head B: Oil resistance

- Good resistance to ASTM 1 oil and mineral oils. Limited resistance to hydraulic oils. If other oils are used, the resistance must be checked in relation to the application.

- Head B: Acid and alkali resistant

- Chemical resistance tested according to ECOLAB. If other media are used, the material resistance must be tested according to the application.

- Head B: Pollution degree

- 3

- Cable: Acid and alkali resistant

- Good (analogue FDA 21 178.3620, 178.3297, 177.1520)

- Cable: Silicone-free

- Yes

Commercial data

- Eclass

- 27060311

3D-Model

3D-Model

Generating CAD-Models requires an external login to CADENAS.

Downloads

Data sheet

-

Data sheet – CAM12.A5-11249701

-

Data sheet – CAM12.A5-11249701

-

Data sheet – CAM12.A5-11249701

Certificates / approvals

EPLAN

-

Link to dataportal