Product portfolio

Your benefits

SinCos HeavyDuty rotary encoders from Baumer reliably and permanently operate in 24/7 operation under the toughest conditions. They make a significant contribution to the prevention of failures and high standstill costs and thus make a key contribution to the high availability of your machine or system.

- Highest availability and unrivalled durability under harshest ambient conditions

- Proven HeavyDuty design, double-sided bearing setup, HeavyDuty connection technology, highly robust sensing

- Failure safety in any environment

- Extremely durable aluminum or stainless steel housing, outstanding corrosion resistance (up to category C5-M), long-term stable sealing concept, operating temperature up to +100 °C (as option -50 °C)

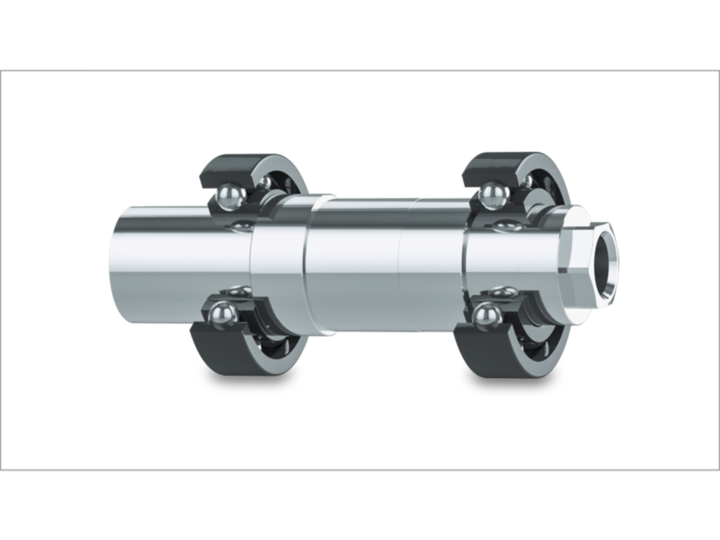

- Efficient protection against bearing damage

- Double-sided bearing setup (where possible), generously dimensioned bearings with large bearing spacing, high bearing load reserve for large radial / axial shaft loads, no inductive shaft currents due to isolated bearings or hybrid bearings with ceramic balls

- Improved control quality, reduced drive heating and improved energy efficiency

- Excellent sine wave signal quality thanks to LowHarmonics® technology, SinCos signals with negligible harmonic content

- Standard explosion protection

- ATEX certification Ex II 3G / 3D for Zone 2 for almost all devices

- Large variety of designs and features

- High-resolution up tos 5000 sine periods, redundant sensing, ual shaft design for mounting of additional devices, encoder combination with centrifugal switch (FSL) or electronic speed switch (ESL)

Applications

Incremental HeavyDuty encoders deliver speed and angular information. Resolution defines by the number of pulses per revolution (square signals) respectively the number of sine wave periods (Sin/Cos signals) per revolution. With every shaft turn, the encoder transfers the information to the upstream control. Higher resolutions are achieved by interpolation of the Sin/Cos signals, either in the control or by using interpolation controllers.

The upstream control identifies the current speed by the pulse numbers counted within a defined time period, while the current position information is identified by the counted pulses respectively Sin/Cos periods. At system power-on, a reference travel is required since the encoder information may have been lost during power off and further to eliminate any incorrect result caused by any shaft rotation performed while the system was not live.

Incremental HeavyDuty encoders are designed for maximum robustness and durability, with enormous mechanical reserves to ensure reliable performance even in the harshest environments:

- Steelworks and rolling mills

- Port installations and crane technology

- Hoists and lifting platforms

- Underground and open pit mining

- Materials handling equipment

- Large drives and generators

- Wind turbines

Functional principle

Leading edge SinCos signal quality

Outstanding, sea water resistant corrosion protection

Reliable protection against shaft currents

Best electromagnetic compatibility

Durable double-sided bearing setup

Downloads

Brochures / Catalogs

-

Brochure – Selection Guide Encoders and angle measurement