Product portfolio

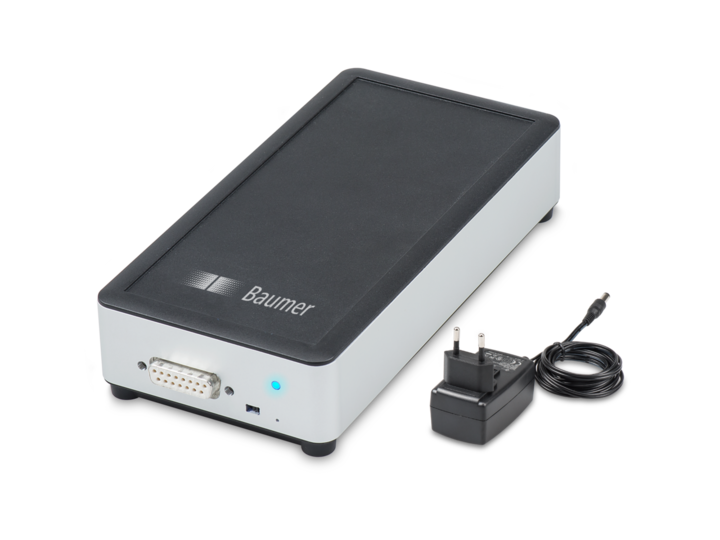

Connecting cable for HMG10P / PMG10P to WLAN-Adapter

HMG10P / PMG10P

Incremental version of the configurable rotary encoder

HMG10P / PMG10P incremental

Open in product selectorTutorial

Tutorial | How to program HMG10P and PMG10P

Your benefit

Robust mechanics, reliable electronics, simple installation: our absolute heavy-duty encoders operate reliably in 24/7 operation under the toughest conditions. They significantly contribute to avoid breakdowns and high downtime costs and thus make a decisive contribution to the high availability of your machine or plant.

- Reduction of variants, downtime, maintenance and storage costs

- SSI absolute value, number of incremental pulses and switching speed are flexibly programmable

- Convenient and fast application optimization and troubleshooting

- Monitoring of current encoder signals such as singleturn and multiturn position, speed, rotational acceleration and temperature

- Time-saving integration into your application

- Intuitive access via PC, tablet and smartphone, access to encoders installed in the system, parameter download for easier documentation

- Non-interfering and secure

- Encoder monitoring parallel to encoder communication with the controller, password protection against unauthorised access

- Highest availability and unrivalled durability under harshest ambient conditions.

- Proven HeavyDuty design, double-sided bearing setup, HeavyDuty connection technology, highly robust sensing

- Fail proof in any environment

- Extremely durable aluminum or stainless steel housing, outstanding corrosion protection up to category C5-M, long-term stable sealing concept, operating temperature up to -40 ... +95 °C

- Efficient protection against bearing damage

- Double-sided bearing setup, generously dimensioned bearings with large bearing spacing, high bearing load reserve for large radial / axial shaft loads, no inductive shaft currents due to hybrid bearings with ceramic balls

- Improved control and process quality in the application

- Ultra-robust and precise singleturn position sensing, best electromagnetic compatibilty

- Maintenance free operation

- No wear parts, energy harvesting HeavyDuty revolution counter MicroGen without battery and without gear

Applications

Absolute HeavyDuty encoders deliver the absolute angular position of shafts, for example rotor shafts in electric motor or cable drums at container cranes. Singleturn encoders acquire the absolute position within one turn of the encoder shaft, while multiturn encoders additionally provide the number of turns completed by the encoder shaft. Usually, referencing of absolute encoder shaft position is carried out during commissioning. In this way, the need for reference travel after power-on is eliminated.

In addition to the absolute position output via serial digital interfaces such as SSI or fieldbuses, absolute HeavyDuty encoders still allow the output of the incremental position, for example, as HTL / TTL signals, for simple processing in speed controllers with incremental input. Individual HeavyDuty encoder versions are also available with speed switches, which report a too high or too low speed via a switch output.

Absolute HeavyDuty encoders are designed for maximum robustness and durability, with enormous mechanical reserves to ensure reliable performance even in the harshest environments:

- Steelworks and rolling mills

- Port installations and crane technology

- Hoists and lifting platforms

- Underground and open pit mining

- Materials handling equipment

- Large drives and generators

- Wind turbines

One can parameterize the resolution of the SSI absolute position, the incremental resolution from 1 to 131072 pulses per revolution and the switching speed from 2 to 12000 rpm. In combination with a wide range of mechanical, signal and fieldbus interfaces, there are virtually no limits to the flexible use of this encoder series.

Technology

Intelligent HeavyDuty encoders

Intuitive programming with web browser

Offline mode

Online mode

Hübner Berlin – the original from Baumer

Proven HeavyDuty principle

Downloads

Brochures / Catalogs

-

Brochure – Absolute HeavyDuty encoders HMG10 / PMG10

-

Brochure – Wireless LAN adapter for programming of encoders HMG10P and PMG10P