Collision avoidance

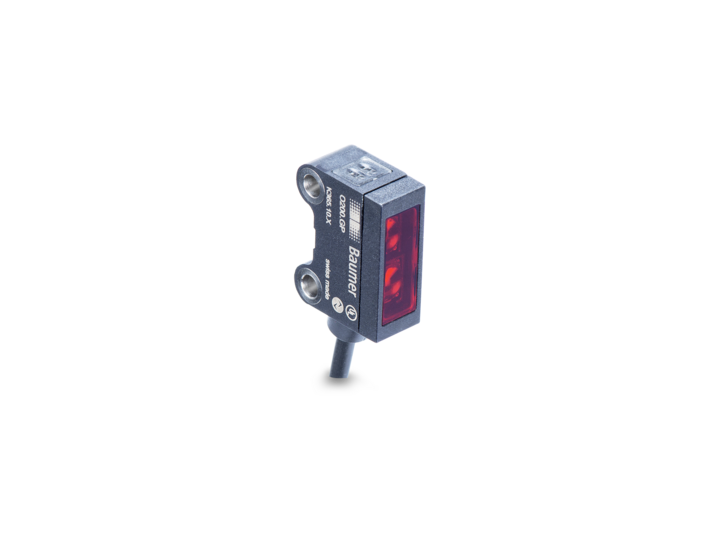

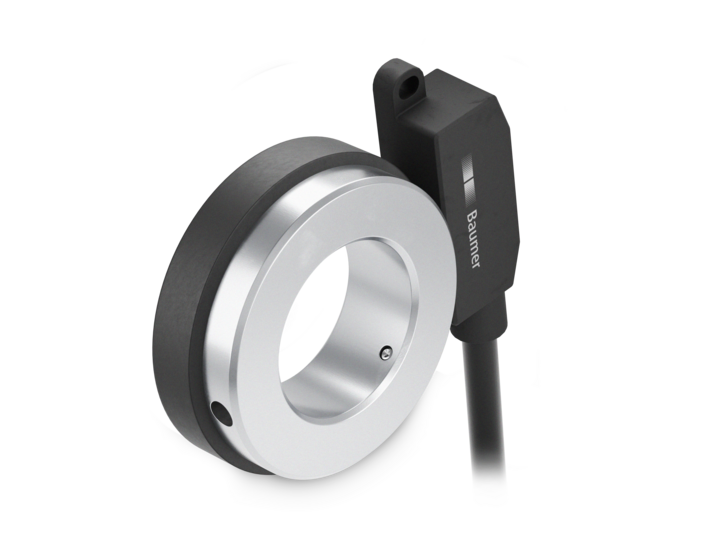

To avoid collisions, the distance between the shuttles must be measured. For this purpose, time-of-flight distance measurement sensors are the right solution:

Your benefits:

- Reliable detection of objects on the lane allows highest availability

- Compact sensors with extended sensing range up to 10 m on a reflector tape allow more flexibility for your shuttle design