USA

us

English

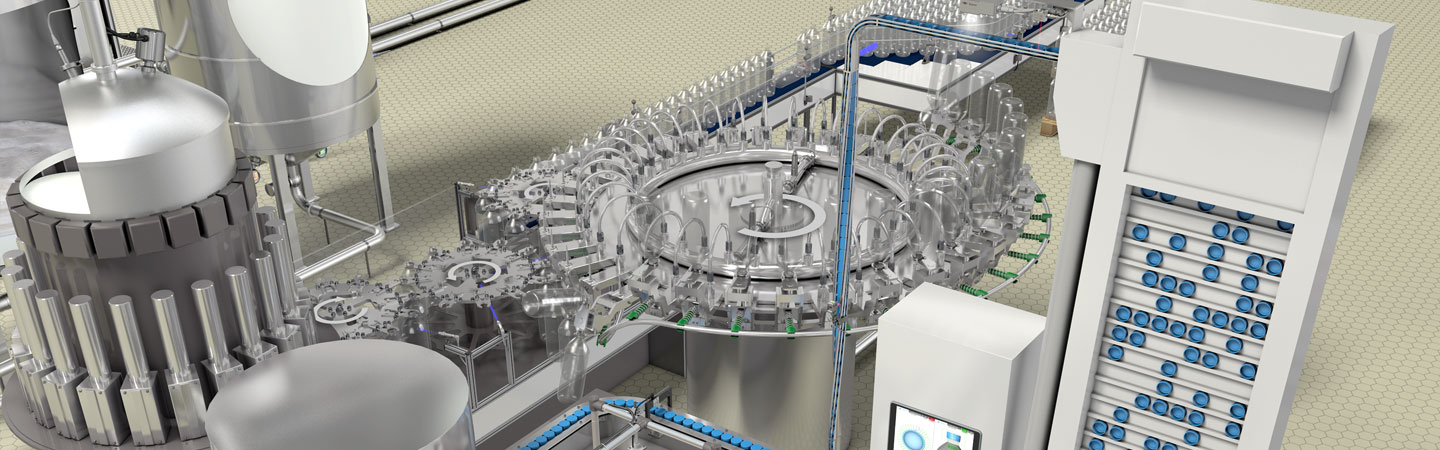

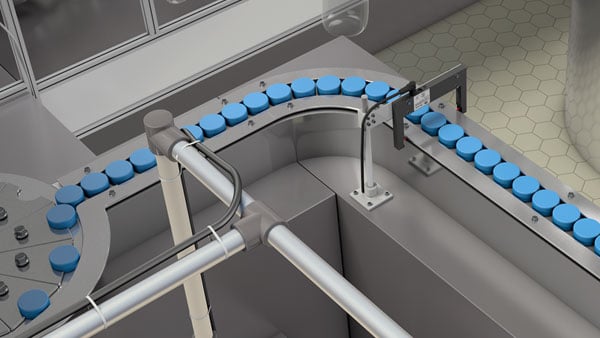

The demands placed on capping machines in terms of performance and flexibility are ever increasing. We support all types of closures for the most diverse requirements in the pharmaceuticals and cosmetics as well as the food and drink industries. This ensures hygienic standards are achieved, thus allowing these machines to also be used as aseptic cappers.

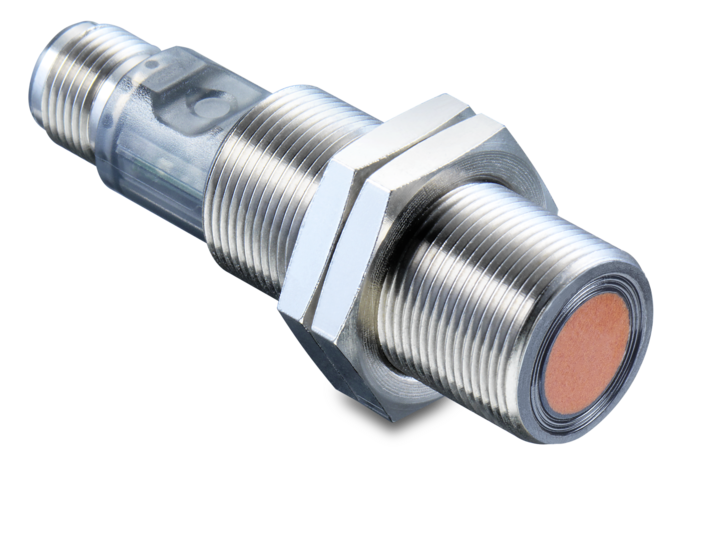

Cap level monitoring in the bin

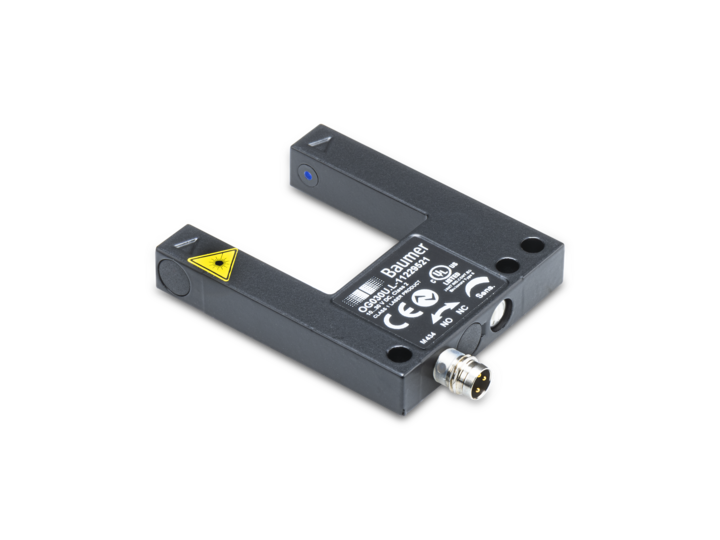

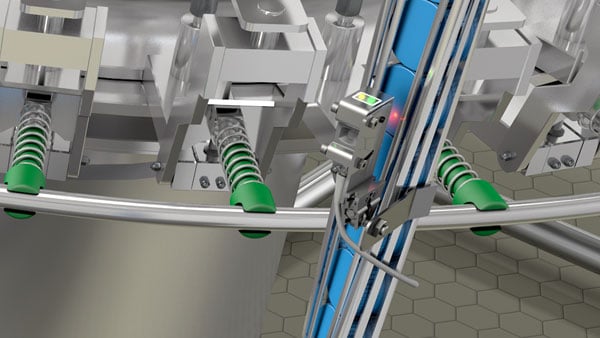

Trigger sensor in wet and cleaning zone for smart camera

SmartReflect – light barrier with no reflector for detecting caps

Reduced production costs and times

- Visible light spot for easy sensor alignment

- No reflector necessary

High operational reliability

- High machine flexibility as different colors and shapes are reliably detected

- Immunity to background reflections ensures a stable detection process

Low service costs

- Enclosure protection class IP 68/IP 69K and proTect+

- Ecolab certified

Checking screw caps with freshness seal for deformation

Image-based quality control with vision sensors

High production security

- Reliable monitoring of caps with freshness seal with patented FEX® contour detection down to 1/4 pixel accuracy

- Up to 6000 checks/minute

Reduced servicing and startup costs

- Stainless steel enclosure of washdown design and protection class IP 69K (tested at 80 °C and 100 bar pressure)

- User-friendly sensor configuration in four simple steps

Cap infeed buffer full

Diffuse sensors with background suppression

Reduced production times and costs

- Visible light spot for easy sensor alignment

- No reflector necessary

High machine availability

- Reliable detection of different colors and shapes

- Unaffected by background reflections and extraneous light

Preparing caps for takeup

Laser fork light barrier

Reduced installation and decision-making costs

- No alignment of transceiver necessary

- Fork width from 20 mm to 120 mm

High machine availability

- Through beam principle for secure detection process

- Unaffected by extraneous light < 100 kLux