Innovation by integration

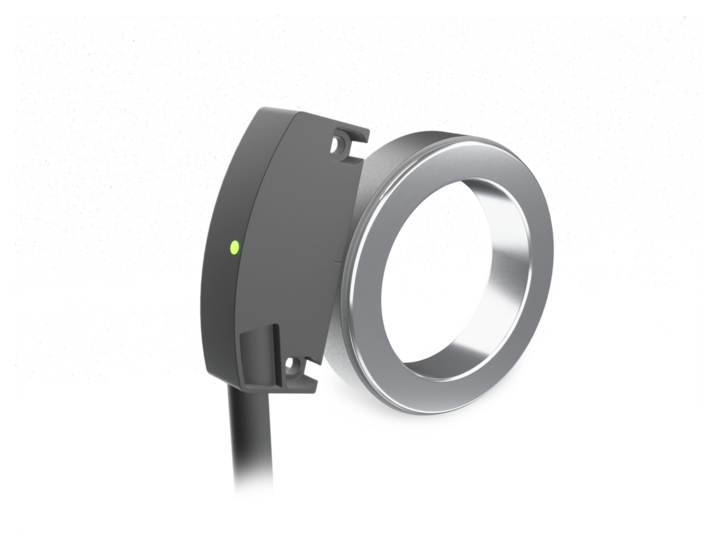

Compared to bearing-mounted systems, bearingless encoders are very space-saving due to their shallow installation depth. With their compact design and suited for large shaft diameters they easily integrate into existing mechanics. No unprotected, expensive outdoor installations.

Your benefits

- Low development and manufacturing costs

- Due to flexibility in shaft diameters from 6 mm on to more than 3 m, the encoder will adapt to your design and not vice versa

- Compact machine construction

- Shallow installation depth thanks to radial sensing

- Solutions with installation depths of less than 12mm

- Integration flexibility through A- or B-side mount

- Reliable long-term operation even under extreme conditions

- Wear-free non-contact magnetic sensing

- Resistant to dirt

- Resistant to shocks and vibration

- Excellent speed quality thanks to precise magnetization

- High-precision magnetic wheels thanks to long-year magnetization expertise

- Long-term high IP protection

- The bearingless design and fully encapsulated electronics allows for cost-efficient but yet high IP protection

- Even at high speed the encoder is protected against water and dust ingress

- Improved robustness by electronics being decoupled from moving parts

- Immune to shaft currents

- Particularly in rotary encoders installed at powerful electric drives, ball bearings may be damaged by shaft currents

- The sensor head being decoupled from shaft will solve the problem

- Easy-to-implement redundancy

- Two sensor heads on a single magnetic wheel is redundant sensing made easy

- Two sensor heads on a single magnetic wheel is redundant sensing made easy

Applications

Intralogistics and AGVs

Textile machinery

Machine tools

Technological highlights

Magnetic sensing allows large gaps between sensor system and magnetic measure (usually magnetic wheel or center magnet).

This way they can be positioned separated from each other, and eliminates the need for precision ball bearings usually applied in rotary encoders.

In parallel, this allows for high mounting tolerances. This provides more flexibility in design and assembly. As there is no need for bearings, there is no wear either.

This way the encoders withstand dust, dirt or textile fibers. They are immune to shaft currents or bearing loads and robust against vibration and shock.