Product portfolio

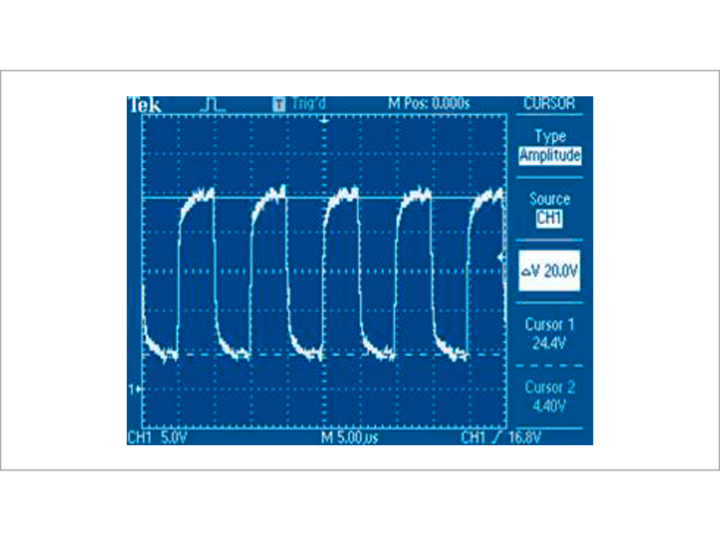

SinCos output – LowHarmonics for excellent signal quality

HOGS100 / HOGS100S

Open in product selectorYour benefits

The HOG10 / POG10 series is the most versatile product family of incremental HeavyDuty rotary encoders. It is based on the enormous experience of the HeavyDuty world market leader, and always offers you an unrivalled robust and durable solution for your application.

HOG10 / POG10 rotary encoders operate reliably and permanently in 24/7 operation even under the toughest conditions. They make a significant contribution to the prevention of failures and high standstill costs and thus make a key contribution to the high availability of your machine or system.

- Highest availability and unrivalled durability under harshest ambient conditions

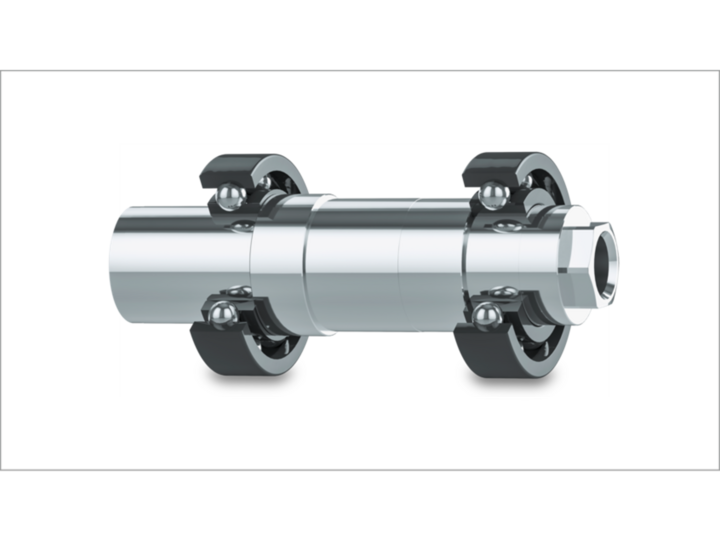

- Proven HeavyDuty design, double-sided bearing setup, HeavyDuty connection technology, highly robust sensing

- Failure safety in any environment

- Extremely durable aluminum or stainless steel housing, outstanding corrosion resistance (up to category CX (C5-M)), long-term stable sealing concept, operating temperature up to +100 °C

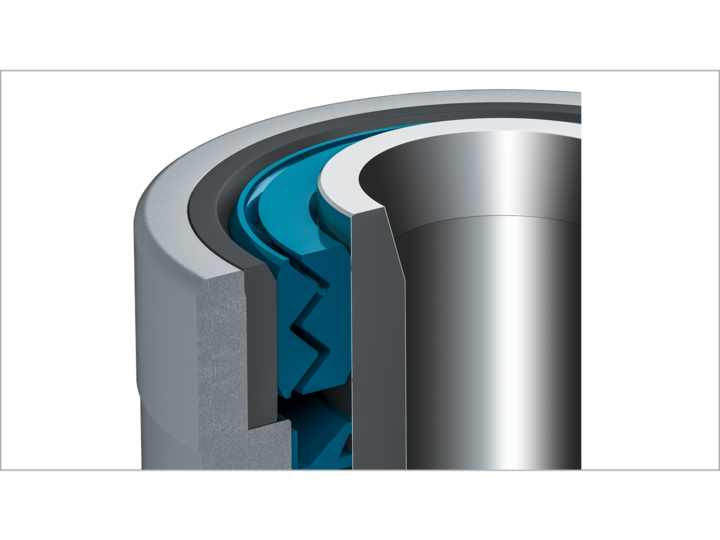

- Efficient protection against bearing damage

- Double-sided bearing setup (where possible), generously dimensioned bearings with large bearing spacing, high bearing load reserve for large radial / axial shaft loads, no inductive shaft currents due to hybrid bearings with ceramic balls

- Improved control quality and process control in the application

- Interference-proof, precise sensing with Opto-ASIC, best electromagnetic compatibility

- Reliable signal transmission over long distances

- Powerful output drivers for cable lengths up to 350 m (HTL-P) or 550 m (TTL), signal transmission via optical fiber up to 1500 m

- Standard explosion protection

- ATEX certification Ex II 3G / 3D for Zone 2 for almost all devices

- Easy and flexible product selection

- All common mounting types (hollow shaft, cone shaft, shaft with EURO flange B10), connection via HeavyDuty terminal box, output signals HTL-P / TTL / SinCos / optical fiber

- Large variety of designs and options

- High-resolution up to 10 000 ppr, function monitoring EMS, redundant sensing, dual shaft for mounting of additional devices, twin encoders, encoders combined with centrifugal switch (FSL) or electronic speed switch (ESL), housing base B3, DNV certificate

- Convenient diagnostics for higher availability

- Permanent supervision of numerous rotary encoder functions with function monitoring EMS, detection of connection errors already during assembly, shortening commissioning and error search

Applications

Incremental HeavyDuty encoders deliver speed and angular information. Resolution defines by the number of pulses per revolution (square signals) respectively the number of sine wave periods (Sin/Cos signals) per revolution. With every shaft turn, the encoder transfers the information to the upstream control. Higher resolutions are achieved by interpolation of the Sin/Cos signals, either in the control or by using interpolation controllers.

The upstream control identifies the current speed by the pulse numbers counted within a defined time period, while the current position information is identified by the counted pulses respectively Sin/Cos periods. At system power-on, a reference travel is required since the encoder information may have been lost during power off and further to eliminate any incorrect result caused by any shaft rotation performed while the system was not live.

Incremental HeavyDuty encoders are designed for maximum robustness and durability, with enormous mechanical reserve capacity to ensure reilable performance even in the harshest envrionments:

- Steelworks and rolling mills

- Port installations and crane technology

- Hoists and lifting platforms

- Underground and open pit mining

- Materials handling equipment

- Giant motors and generators

- Wind turbines

Technology

Durable double-sided bearing setup

Hübner Berlin – the original from Baumer

Proven HeavyDuty principle

Outstanding, sea water resistant corrosion protection

Long-term stable sealing concept

Reliable protection against shaft currents

Best electromagnetic compatibility

High-power signal output drivers

EURO flange B10

Integrated function monitoring

Leading edge SinCos signal quality

Large variety of HeavyDuty combinations

Downloads

Brochures / Catalogs

-

Brochure – Selection Guide Encoders and angle measurement