Poland

pl

English

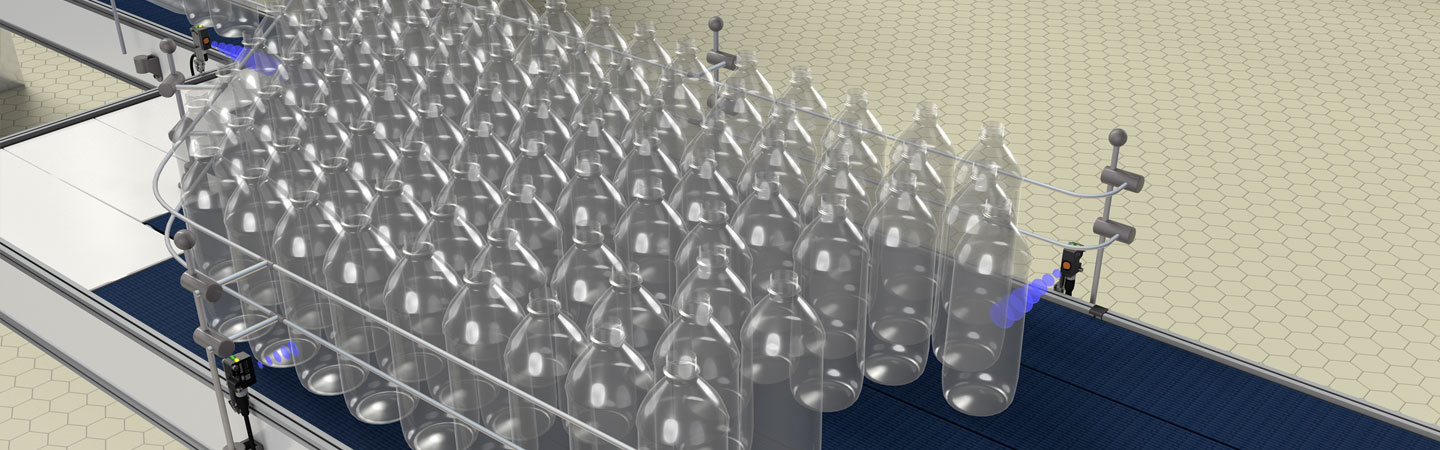

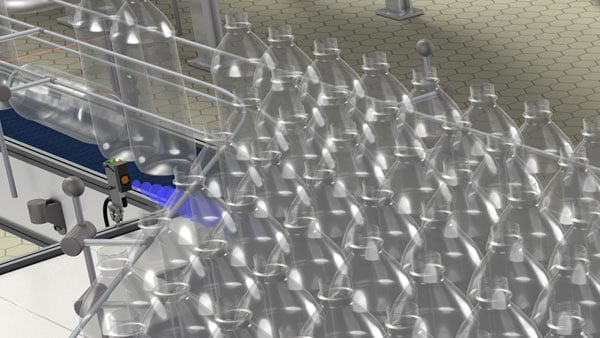

Buffer tables are monitored by sensors in order for modern filling and packaging machines to achieve the greatest possible efficiency. Irrespective of the buffer capacity and container variance, Baumer sensors monitor the no-pressure backup of large quantities over the smallest possible area. This ensures system downtimes are reduced to a minimum.

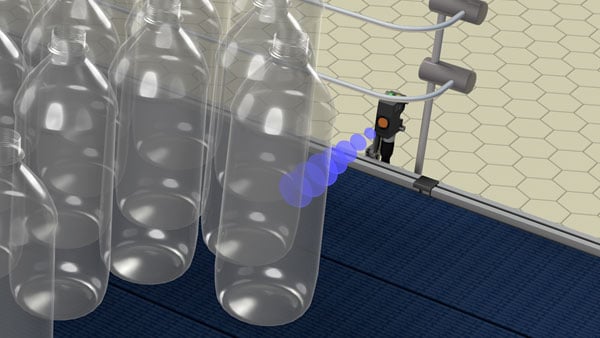

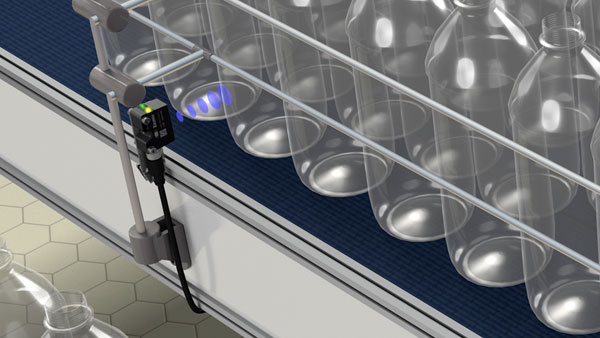

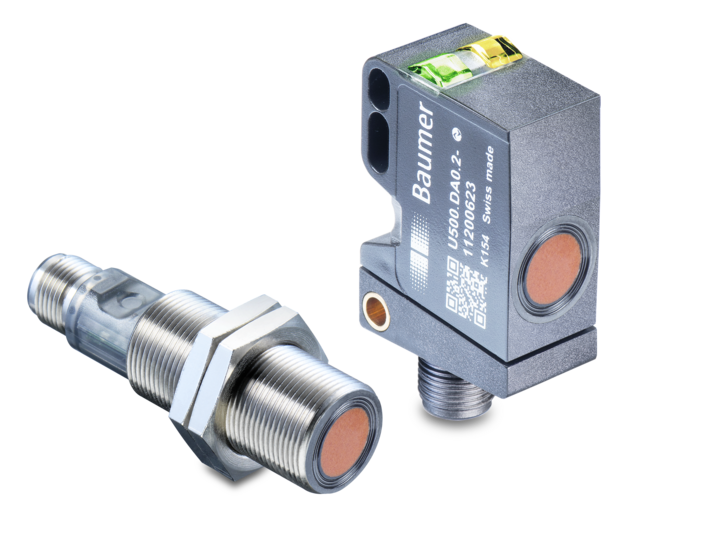

Ultrasonic proximity switch for reliable detection

Ease of selection and planning – reducing costs

- Ultrasonic proximity switch for high packaging variance

- Detection range from 20 mm to 1000 mm

Reduced setup and maintenance times

- Fast adaptation to different applications by setting the sound beam width (e.g. narrow sound beam for individual objects and broad sound beam for groups of objects)

- Adjustable filter functions for an optimum between response time and repeatability

- Flexible adjustment of switching point with qTeach® or IO-Link

- Direct detection of packaging