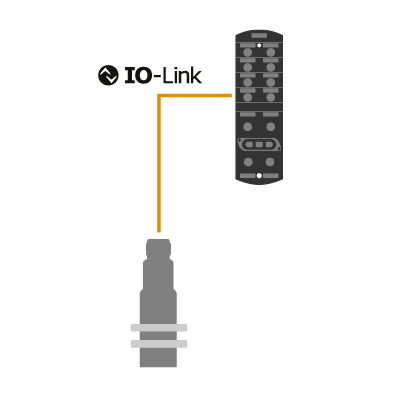

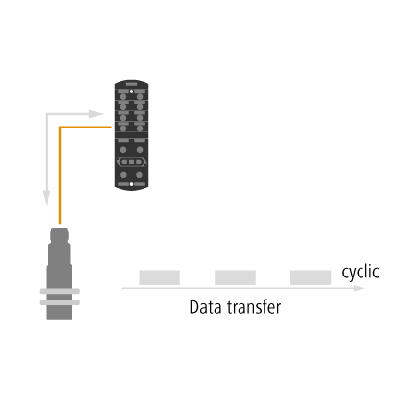

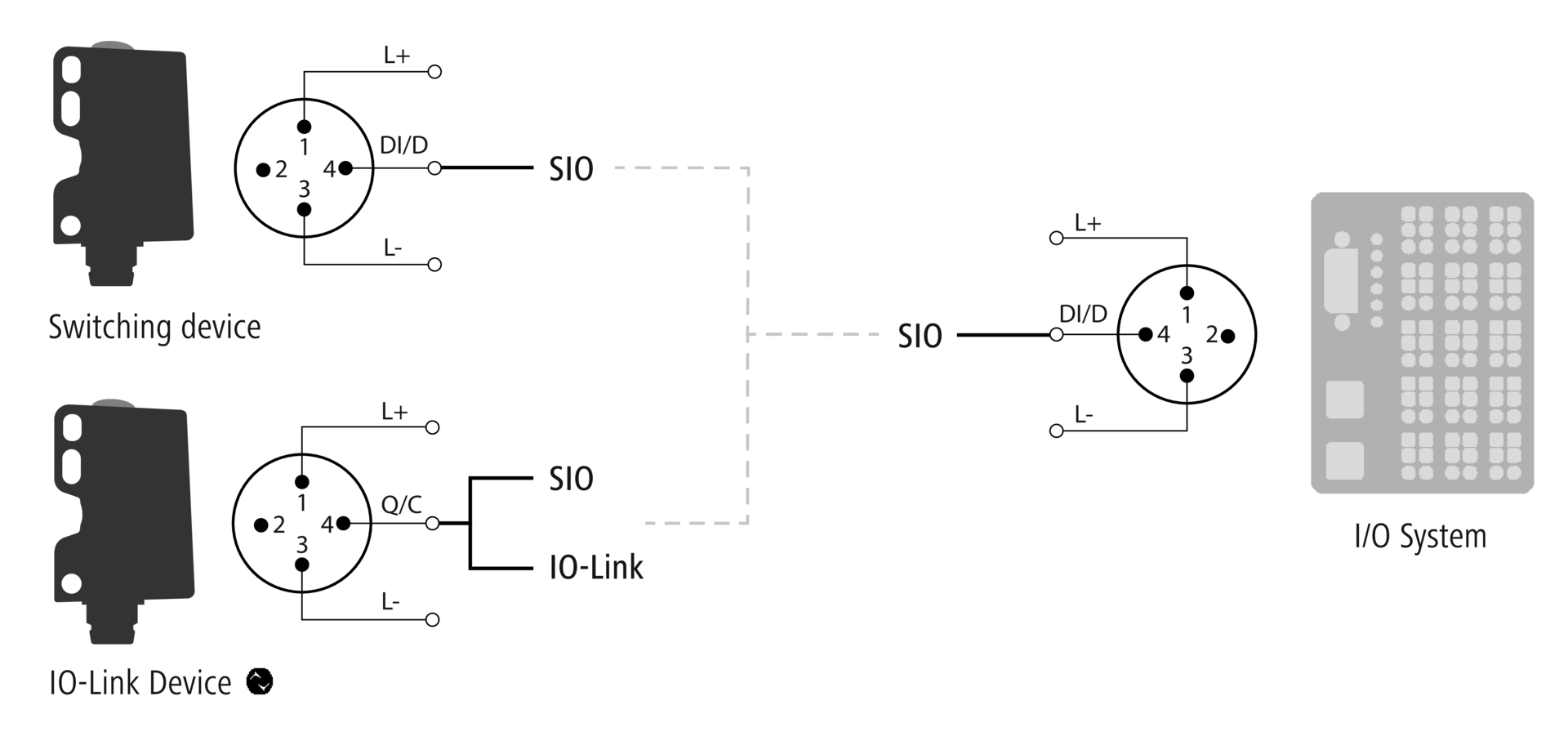

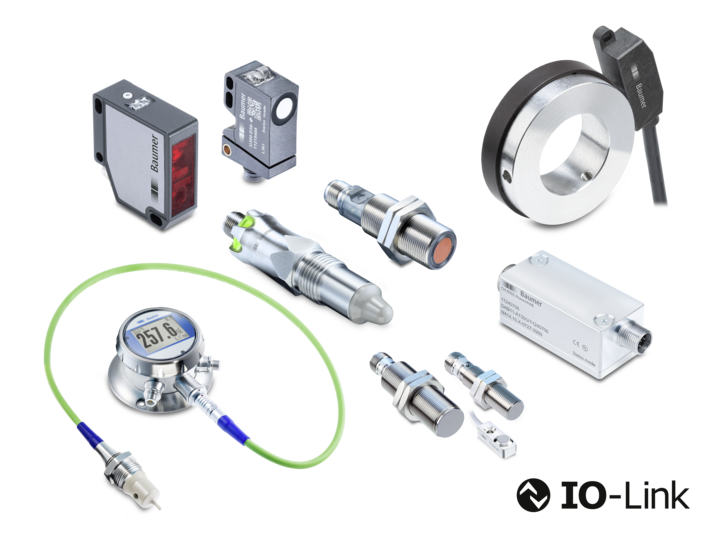

IO-Link is a manufacturer-independent digital communication protocol. It enables bidirectional point-to-point communication, including the exchange of process data, parameters for configuration as well as event and diagnostic data for feedback on faults or additional information. All IO-Link connections are established between an IO-Link master and an IO-Link device (actuator or sensor). These devices are connected to the IO-Link master via unshielded 3-pole standard M8/12 cables. IO-Link is available for a wide range of sensor technologies and can also be integrated into small miniature sensors.

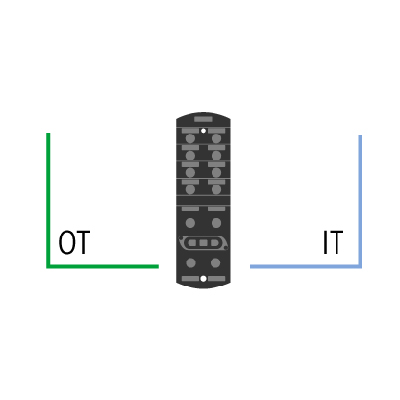

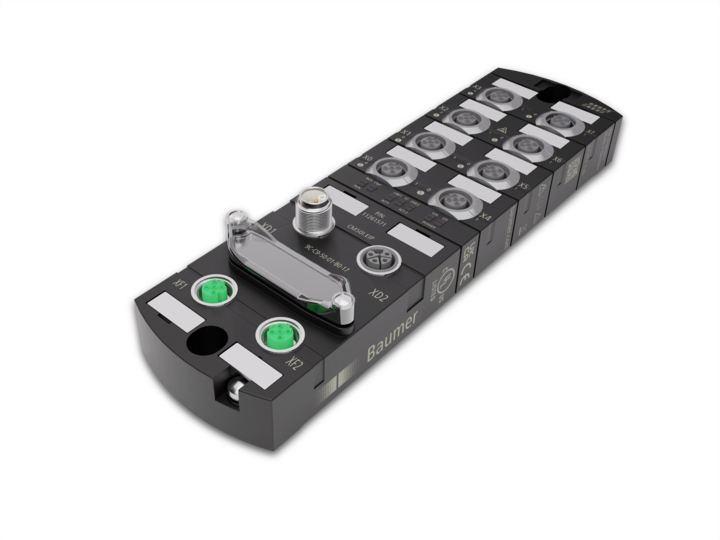

IO-Link masters typically connect to 8 IO-Link devices. The connection to the controller is established via industrial Ethernet protocols (operational technology (OT)). In addition, several IT protocols like OPC UA, MQTT and JSON REST are supported over the same network line. This allows maintenance or management to access sensor data without affecting the OT speed or reliability.