Netherlands

nl

English

Your benefits

- Chemical resistance

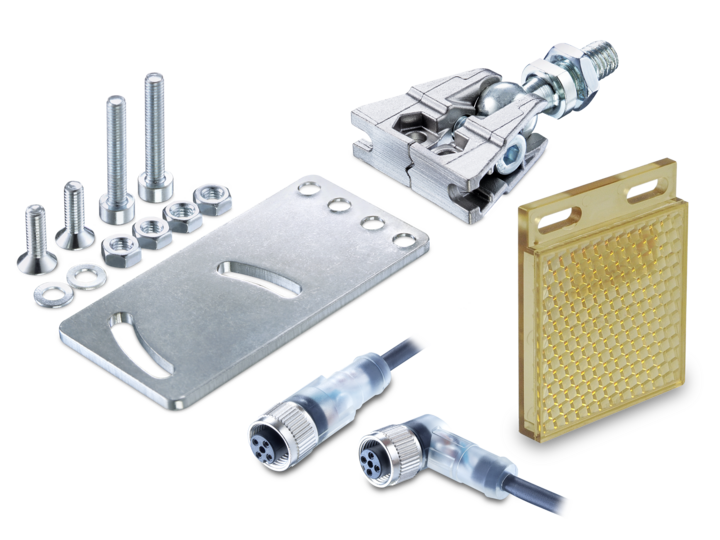

- The sensor housings are made of Polysulfon or stainless steel as resistance against specific fluids

- Detectable media

- Fluid detection by optical light allows for deployment even in varied non-conductive media

- In leakage monitoring, 1 ml escaping fluid will suffice to trigger an alarm

- Easy commissioning

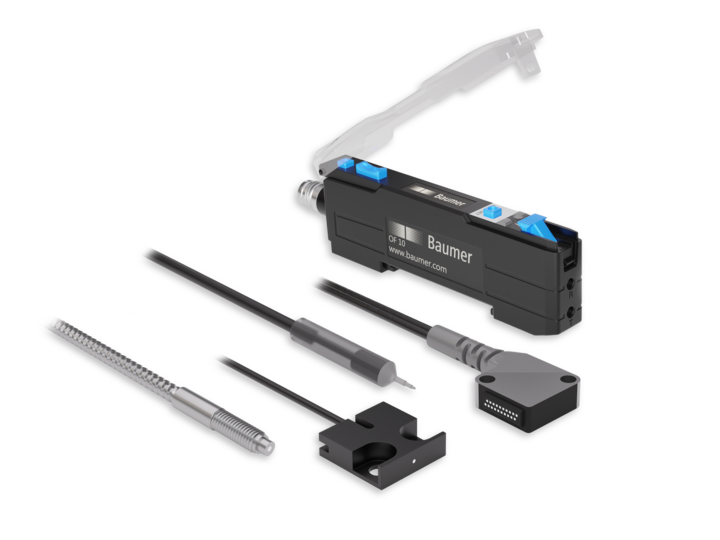

- The sensors with integrated electronics eliminate the need for parameter setting. Fiber-optics sensor settings are made at the related fiber optics device

- Hazardous environments

- The intrinsically safe fiber optic variant with PFA sheath is even suitable for hazardous areas

- Fail-safe behavior

- The integrated fail-safe behavior function will trigger an alarm in the event of leakage, cable break, sensor defect or if the sensor has come off the mount

Applications

The sensor's chemical resistance opens a wide application range:

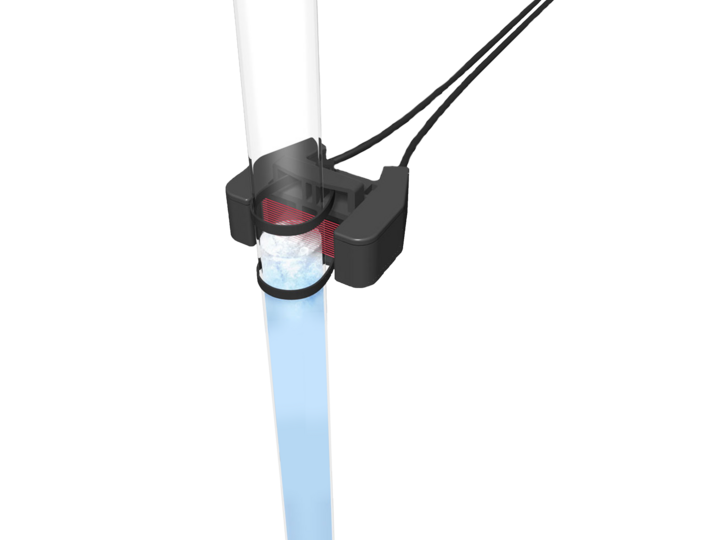

- Level monitoring in liquids such as acetone, acids, alkalis, mineral oils, milk and any non-conductive fluid

- Non-contact level detection in (semi-)transparent hoses and riser tubes

- Minimum and maximum level detection in tubs and tanks

- Leakage monitoring in oil tubs or lubricant tanks

- Leakage monitoring in dispensers and other fluid dispensing systems

Technology

Downloads

Technical and Application Reports / White Paper

-

Application Report – Fiber optic sensors to detect liquid levels and leakage of fluids