A question of light

If it gets too dark when reading, a lamp is the answer. If a piece of paper is printed with low contrast, it can be exposed to the sun for better readability. If a photographer wants to put something into perspective, he or she uses colored spotlights. What is useful in everyday life – the correct intensity and type of illumination – is also crucially important for machine vision, as natural lighting is often not available or insufficient or can also be unsuitable or obstructive depending on the application.

For this reason, illumination plays major role in the design of image processing systems. Type, color, and intensity have a major impact on what is visible of a test object and can therefore be captured by a camera or a vision sensor for evaluation. It follows that the purpose of correct illumination is to emphasize the characteristics of a test object in the best possible manner to allow the entire image processing system to function reliably.

Type and position

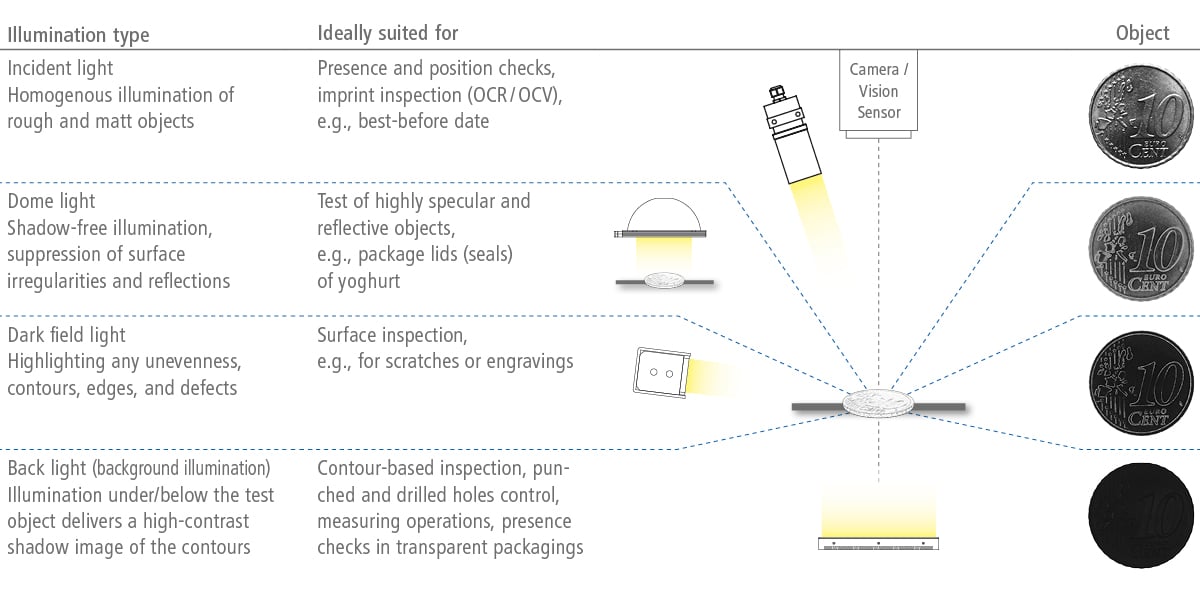

Illumination is divided into incident light, dome light, dark field light, and back light. Based on the different technological approaches, each type of illumination has its respective strengths that can be used for different inspection tasks. For example, if the surface of the object is very reflective, then dome lighting can prevent reflections. If cameras and vision sensors are intended to recognize scratches or engravings, lateral dark field lighting is recommended.

In addition to determining what should be made visible of a test object, other aspects need also be taken into account, e.g., material characteristics such as the nature and color of the surface, ambient conditions such as external incident light, or working distances.

Color

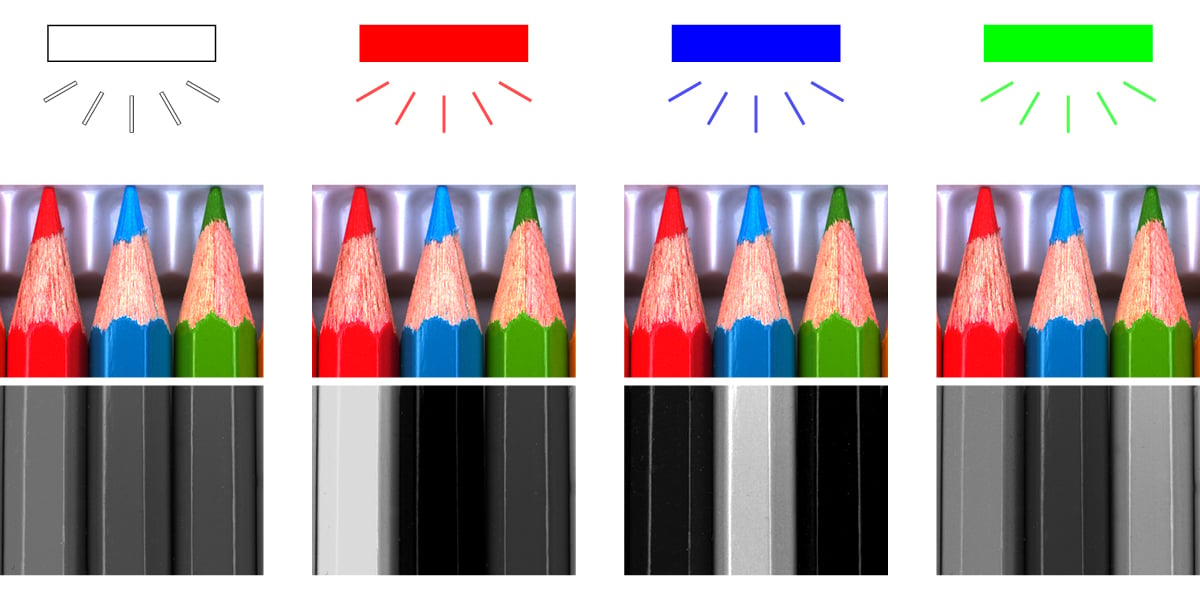

The application of different illumination colors creates contrasts that allow an inspection to be accomplished better or more efficiently. A color camera, for example, is not always required. Colored illumination can highlight or suppress certain colors in monochrome images. For example, if multi-colored surfaces such as colored pencils are exposed to blue light then the blue surfaces reflect the light the strongest while the other surfaces absorb it to varying degrees, depending on the color. The result is that the blue pencil appears very bright, and areas with extensive red components appear very dark. In this way, contrasts can be created that are decisive for a successful application solution.

Do you have questions?

Finding the correct illumination for applications depends on many factors; it is a very individual and potentially very complex process. Do you have questions regarding this? Our team will be glad to advise you and help you to find the best solution.

Product portfolio

You may also be interested in

Downloads

Brochures / catalogues

-

Brochure – High-performance industrial cameras

-

Brochure – VeriSens vision sensors