Product portfolio

Your benefits

The next generation of absolute HeavyDuty encoders HMG10 / PMG10 is the perfected and revolutionary approach that merges the proven double-sided bearing setup with magnetic high-precision sensing and the patented Energy Harvesting micro-generator, which has been standing the hard test of HeavyDuty use for more than 10 years. The outcome is the new absolute reference standard for HeavyDuty encoders. With even further enhanced robustness and a high precision which previously required optical sensing.

- Highest availability and unrivalled durability under harshest ambient conditions

- Proven HeavyDuty design, double-sided bearing setup, HeavyDuty connection technology, highly robust sensing

- Failure safety in any environment

- Extremely durable aluminum or stainless steel housing, outstanding corrosion protection up to category C5-M, long-term stable sealing concept, wide operating temperature range of -40 ... +95 °C

- Efficient protection against bearing damage

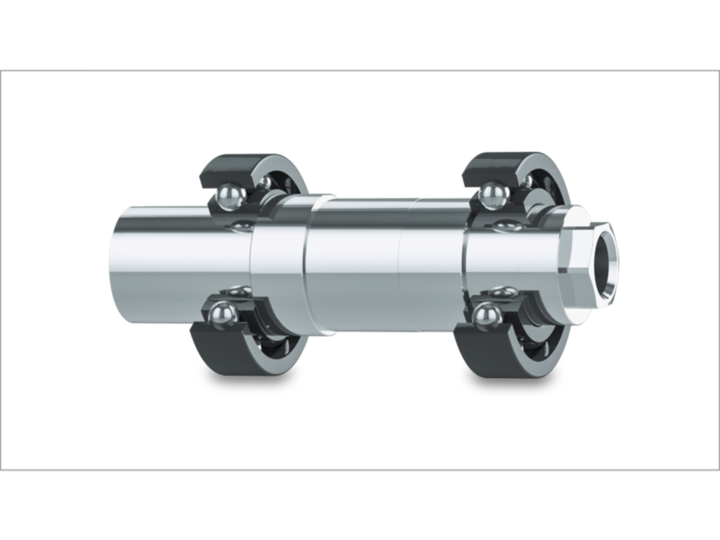

- Double-sided bearing setup (where possible), generously dimensioned bearings with large bearing spacing, high bearing load reserve for large radial / axial shaft loads, no inductive shaft currents due to hybrid bearings with ceramic balls

- Improved control and process quality in the application

- Ultra-robust, precise magnetic singleturn position sensing with optical precision, additional high-precision incremental signals, best electromagnetic compatibilty

- Maintenance free operation

- No wear parts, energy harvesting HeavyDuty revolution counter MicroGen without battery and without gear

- Simple and flexible product selection

- Extensive portfolio, all relevant shaft, flange and connector versions, all relevant interfaces, additionally incremental signals with zero pulse, parameterizable speed switch

Applications

Absolute HeavyDuty encoders deliver the absolute angular position of shafts, for example rotor shafts in electric motors or cable drums on container cranes. Singleturn encoders acquire the absolute position within one turn of the encoder shaft, while multiturn encoders additionally provide the number of turns completed by the encoder shaft. Usually, referencing of absolute encoder shaft position is carried out during commissioning. In this way, the need for reference travel after power-on is eliminated.

In addition to the absolute position output via serial digital interfaces such as SSI or fieldbuses, absolute HeavyDuty encoders still allow the output of the incremental position, for example, as HTL / TTL signals, for simple processing in speed controllers with incremental input. Individual HeavyDuty encoder versions are also available with speed switches, which report a too high or too low speed via a switch output.

Absolute HeavyDuty encoders are designed for maximum robustness and durability, with enormous mechanical reserves to ensure reliable performance even in the harshest environments:

- Steelworks and rolling mills

- Port installations and crane technology

- Hoists and lifting platforms

- Underground and open pit mining

- Materials handling equipment

- Large drives and generators

- Wind turbines

Technology

Energy harvesting HeavyDuty revolution counter

Long-term stable sealing concept

Outstanding, sea water resistant corrosion protection

Hübner Berlin – the original from Baumer

Proven HeavyDuty principle

Ultra-robust high-precision absolute magnetic singleturn sensing

High-power signal output drivers

Best electromagnetic compatibility

Reliable protection against shaft currents

EURO flange B10

Durable double-sided bearing setup

Downloads

Brochures / Catalogs

-

Brochure – Absolute HeavyDuty encoders HMG10 / PMG10