Product portfolio SWIR cameras

Software, tools, application notes

Your benefits

Short Wavelength Infrared (SWIR)

ATTENTION: This product is subject to statutory export control regulations and may require written information on intended end use and final destination! Dual Use Classification ECCN/AL: 6A003B

SWIR technology

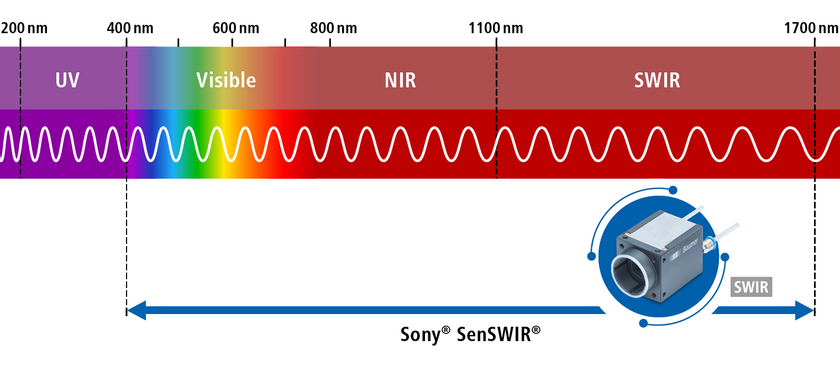

The Baumer SWIR industrial cameras of the CX.XC series are industry-capable GigE Vision short-wave infrared cameras. Integrating highly sensitive Sony SenSWIR InGaAs sensors, these cameras feature image acquisition both in the spectrum of visible and non-visible light, i.e. wavelength 400 to 1700 nm.

This way, the technology opens up new application potentials with high precision requirements, as for example in the food industry as well as the semiconductor and pharmaceutical industries.

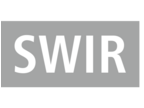

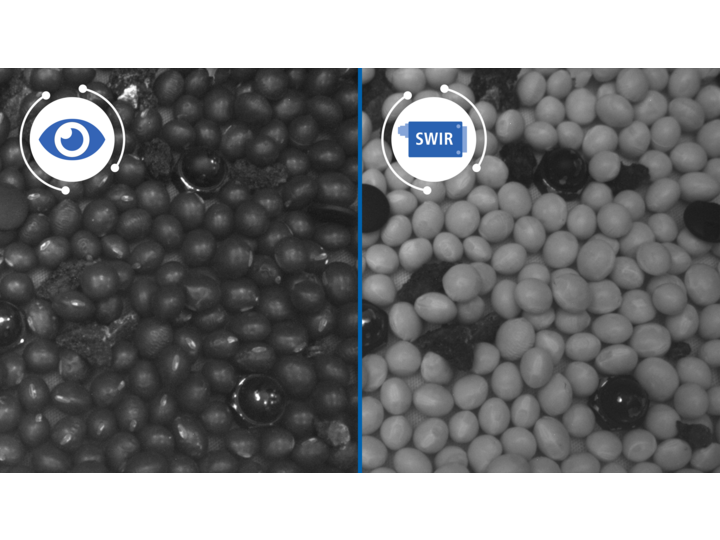

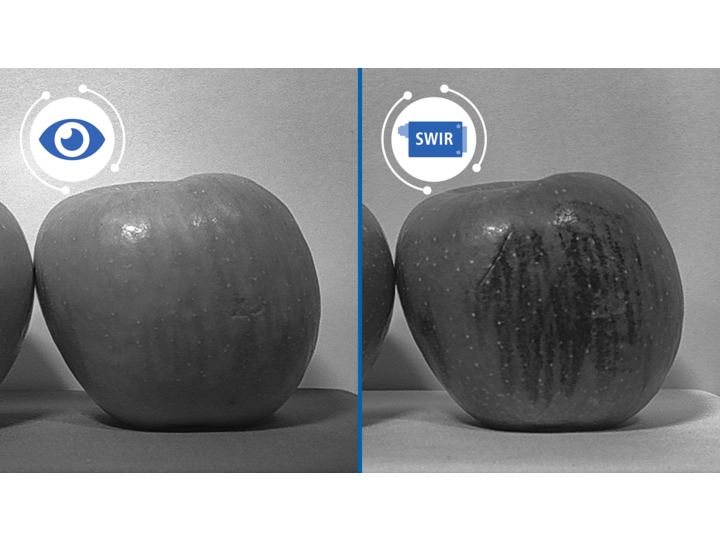

SWIR application examples

Applications

Short Wavelength Infrared (SWIR) technology

Food industry

Semiconductor industry

Pharmaceutical industry

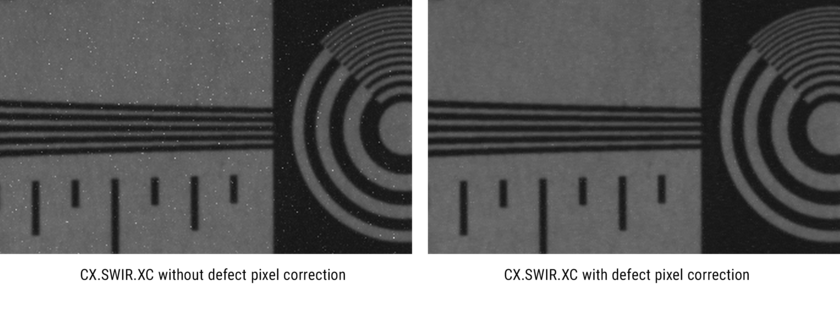

Defect Pixel Correction

How to avoid defect pixels for SWIR applications – made by Baumer

InGaAs sensors show significant more defect pixels due to technology compared to silicon-based CMOS sensors.

Example: Image without any corrections (left) | Image with combined static and dynamic defect pixel correction (right)

(Image acquisition Sony IMX990: 1,350 nm, Use at ambient temperature: typical temperature at the image sensor 35°C)

Why is it important to avoid defect pixels?

To reach an excellent image quality and a stable running image processing system each avoided defect pixel counts.

What needs to be considered when using cameras with InGaAS sensors?

A low temperature at the image sensor is crucial in order to keep the number of defect pixels low.

The solution – made by Baumer

CX.SWIR.XC cameras provide a combination of both a perfect thermal industrial design and an integrated static and dynamic defect pixel correction matched to the sensor. The temperature at the image sensor can be further reduced by using the integrated cooling pipe.

1. Avoid defect pixels

2. Additional defect pixel correction

3. Integrated cooling pipe can be used optionally

Downloads

Brochures / Catalogs

-

Product factsheet SWIR and UV industrial cameras