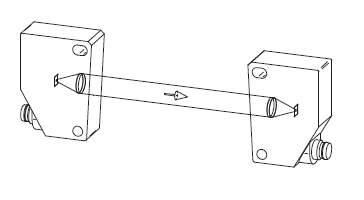

Through beam sensor

Characteristics and advantages

Due to the separated configuration, long ranges with large signal excess gain can be achieved in comparison with equivalent retro-reflective systems. Through beam-sensors are therefore most suitable for operation in unfavorable ambient conditions such as dirt, dust and moisture.

- The clearly defined, consistent active zone permits highly constant repeatability throughout the entire sensing distance.

- The switching point is independent of the surface properties of the object.

Mounting and adjustment

The emitter and receiver must be aimed at each other. The narrower the angle of radiation and reception, the more accurately this must be conducted.

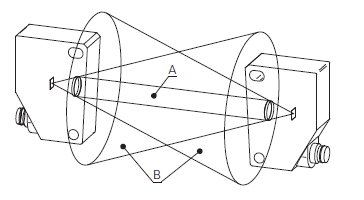

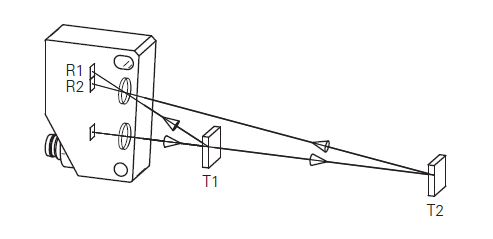

Retro-reflective sensors

The emitter and receiver are installed in the same housing. The emitted infrared, red or laser light is returned by a triple reflector or a reflective film to the receiver. The output changes its state when the object breaks the light beam (sensor receives no light).

Characteristics and advantages

- Single-lens optics

Because the emitted and received beams are on the same axis, the direction of approach of the object is irrelevant, and it is possible to look through small openings. Reflectors can also be used in close-range without signal breakdown

- Short response times

Retro-reflective laser sensors with response times of 0,05 ms and focused laser beams correctly detect the smallest, fast-moving objects (0,1 mm in diameter).

Mounting and adjustment

Each sensor has a separate excess gain curve. As the operating reliability depends heavily on the ambient conditions, it must be ensured that the sensor operates with the highest possible excess signal gain.

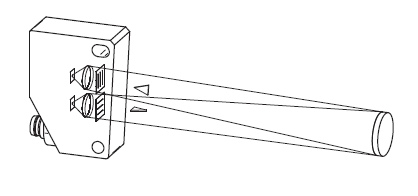

Light barrier without reflector

Contrary to diffuse or through beam sensors, SmartReflect light barriers feature a closed light beam which is set up between the sensor and machine. The sensor switches when an object interrupts the light beam. The only requirement is the presence of a defined background, e.g. a machine part, within the sensing range of the sensor, which closes the light beam.

Characteristics and advantages

Maximum security

- Most secure object detection due to the barrier principle

- Higher process reliability by eliminating the reflector as the weak spot

- No functional impairment due to contamination

Reduced operating costs

- Time savings during installation, as no separate reflector / receiver is necessary

- No regular reflector exchange necessary

- Expensive reflector cleaning is not required

Mounting and adjustment

The SmartReflect light barrier has to be aligned with a machine part within its sensing range. This machine part is then set using the teach-in.

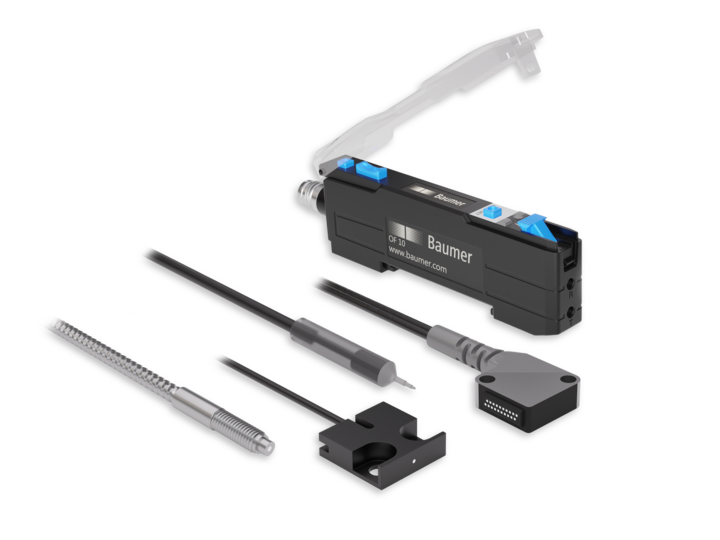

Diffuse sensor with background suppression

By using the triangulation principle, diffuse sensors with background suppression not only measure the light intensity reflected by the target, but also determine the distance of the object from the sensor. In this way, objects with the minimum size of the light beam located within the adjustable sensing distance can be detected regardless of their color and surface.

The diffuse sensors with background suppression and laser light source were developed specifically for applications in which exact positioning is important. With the precisely focused beam, even very small objects such as the wires of a resistor or threads can be clearly detected or counted.

Characteristics and advantages

- Adjustable sensing distance

The switching point can be adjusted accurately between the object and the interfering background using a set screw or Teach-in method

- Largely independent of color

The sensing distance remains constant even if the color of the objects changes. Readjustment is therefore unnecessary. Objects changing in the background also have no effect.

- Small spot size

Laser sensors can detect objects with a size of just 0,1 mm. Sensors with pinpoint diodes have a spot of only 2 mm diameter at the focus.

- Red light emitters

Visible red light permits simple adjustment of the sensor to small objects by eye.

- Short response time

Small, quickly moving objects are reliably detected due to the short response time.

Mounting and adjustment

The diffuse sensor must be aimed at the object. The sensing distance must be set to a distance between the target and the background. The background must be located behind the adjusted sensing distance by at least the distance of the sensing distance reduction of the sensor to black.

Diffuse sensors with intensity difference

The emitter and receiver are in the same housing. The emitted infrared, red or laser light is reflected directly by the target back to the sensor. If the target reflects sufficiently well, the received light causes the sensor to switch.

The light shining on the target is largely diffused and reflected back in all directions. A very small part of this remitted light is observed by the receiver. If the target reflects sufficiently well, the received light causes the sensor to switch. As the sensor operates with the reflection from the materials, the surface properties, color and gloss have a great influence on the switching distance.

Characteristics and advantages

- Suitable to discern black and white

- Relatively large active range

- The sensing distance depends largely on the reflective properties of the object surface

- Positioning and monitoring with just one sensor

- Easy installation

- Short response time

Mounting and adjustment

With diffuse sensors operating by the intensity difference principle, the relative receiving signal is specified. This represents the signal level received from a white object as a function of the distance.

Retro-reflective sensors for transparent objects

The emitter and receiver are installed in the same housing. The emitted infrared, red or laser light is returned by a triple reflector or a reflective film to the receiver. The output changes its state when the object breaks the light beam (sensor receives no light).

Characteristics and advantages

- Polarizing filter

Polarizing filter allow objects to be detected regardless of the texture and color of the surface. Glossy and reflective objects are also reliably detected.

- Transparent objects

Reliably detect transparent objects such as packaging films, PET bottles and glassware.

Mounting and adjustment

Each sensor has a separate excess gain curve. As the operating reliability depends heavily on the ambient conditions, it must be ensured that the sensor operates with the highest possible excess signal gain.

You may also be interested in

Mounting and adjustment

The emitter and receiver must be aimed at each other. The narrower the angle of radiation and reception, the more accurately this must be conducted.