USA

us

English

Product portfolio

UV, NIR, SWIR and polarization cameras

Near Wavelength Infrared (NIR) cameras

LX/CX series (LXG.NIR/VCXG.NIR cameras)

Open in product selectorInspect the invisible

Overview wavelength ranges

- Sony IMX487 UV sensor

- Sony IMX487 UV sensor with 200-400 nm, easy integration via GigE / 10 GigE interface for a wide range of applications

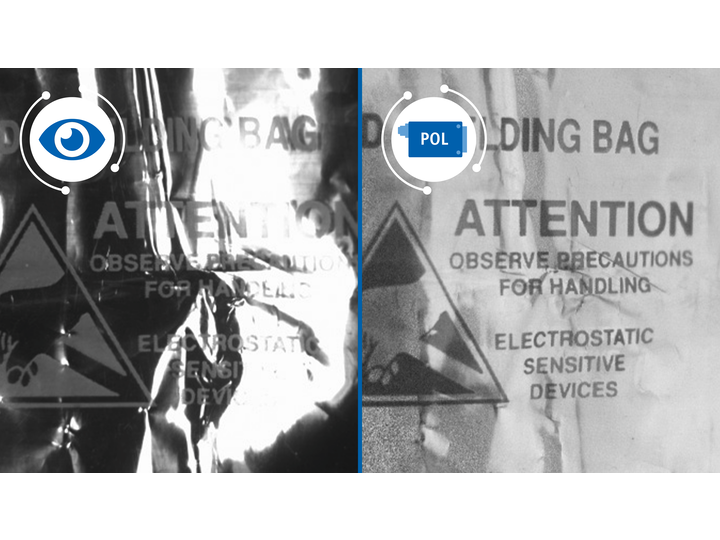

- Sony PolarSens sensors

- Sony PolarSens technology for detecting linear polarization states, suitable for transparent materials

- onsemi PYTHON, ams CMV sensors

- onsemi PYTHON and ams CMV sensors with 800-1000 nm, easy integration via GigE Vision interface

- Sony SenSWIR InGaAs sensors

- High bandwidth and sensitivity of 400-1700 nm in the visible and invisible light range thanks to Sony SenSWIR InGaAs sensors

- Dual Use Classification ECCN/AL: 6A003B

- High bandwidth and sensitivity of 400-1700 nm in the visible and invisible light range thanks to Sony SenSWIR InGaAs sensors

Application Examples

Examples SWIR (Short Wavelength Infrared)

ATTENTION: This product is subject to statutory export control regulations and may require written information on intended end use and final destination! Dual Use Classification ECCN/AL: 6A003B

Examples UV (Ultraviolet)

Examples POL (Polarization)

Downloads

Brochures / Catalogs

-

Brochure – High-performance industrial cameras