USA

us

English

Product portfolio

Miniature sensors with IO-Link

Cubical, slim design

Universal element for attachment to system profiles

Your benefits

Always reliable

Connected

Fast design-in

Optimum sensor setting to the application

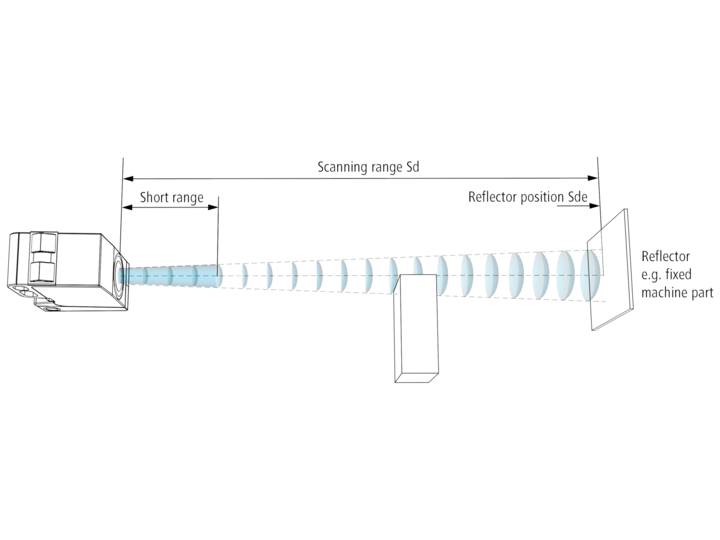

Tutorial | Ultrasonic sensors U300, U500, UR18

Applications

Film crack detection

PCB detection

Limit value detection in containers

Technology

Downloads

Brochures / Catalogs

-

Brochure – Miniature ultrasonic sensors U300

Technical and Application Reports / White Paper

-

Application Report – The smallest and lightest ultrasonic sensors worldwide SONUS

-

Application Report – Precise detection of the smallest objects with ultrasonic sensors Series09